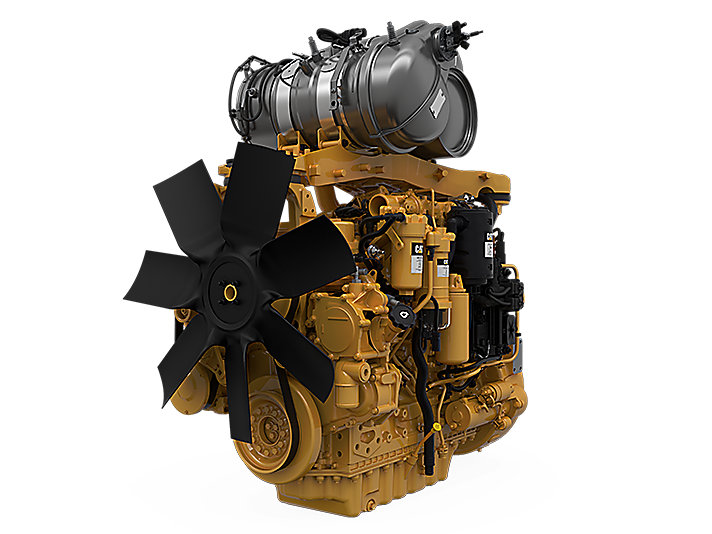

Con uno de los diseños de motor más modulares de Caterpillar hasta la fecha, el Cat C7.1 también cuenta con un postratamiento montado en el motor que ahorra tiempo y espacio valiosos a los OEM cuando se instala en una amplia variedad de máquinas, especialmente en aplicaciones industriales y de construcción. Los OEM también gozan de una reducción del 20 % de largo, 5 % de alto y 40 % del peso cuando se reduce el tamaño de plataformas de 9 litros.

El Cat C7.1 utiliza una tecnología de regeneración pasiva para que los operadores puedan continuar las tareas más difíciles en los entornos más severos sin tener que preocuparse por el motor.

Aplicaciones industriales, agrícolas y de construcción, como por ejemplo: bombas • Compresores • Astilladoras • Rectificadoras • Equipos de pavimentación • Unidades de potencia hidráulica • Equipos para perforación • Plataformas de perforación • Tractores

Son muchos los beneficios al reducir el tamaño, estos incluyen un descenso del 18 % en todo el consumo de combustible cuando se reduce el tamaño de un motor de 6 cilindros. Con un descenso agregado del 3-4 % en todo el consumo del DEF y la integración del EGR, los ahorros de costos no tardan en acumularse.

Mantenimiento programado, garantía incluida, servicio confiable del distribuidor y una red global integral de respaldo del distribuidor: todo es estándar con el Cat C7.1. Consulte a su distribuidor Cat para obtener más detalles.

Validado con muchas horas de pruebas de campo, el Cat C7.1 está fabricado para cumplir con los estándares de seguridad estrictos de Caterpillar y con los sitios de trabajo más exigentes de los clientes en todo el mundo.