These excavators are specifically designed for and manufactured in India, incorporating insights from customers throughout the country.

IRVING, Texas, December 10, 2025 – Caterpillar launches the next generation design for the Cat® 321, 322 and 324 models, built to deliver high performance, long-lasting durability and increased fuel efficiency. An advanced electrohydraulic system provides accurate bucket control, resulting in maximum precision. Extended, synchronized service intervals plus reinforced structures help to improve machine uptime availability and lower operating costs. These excavators are specifically designed for and manufactured in India, incorporating insights from customers throughout the country.

“The next generation Cat excavators are designed to solve our customers’ toughest challenges. Each model delivers increased customer value by catering to their most critical requirements, whether it be highest productivity, lowest fuel consumption or balanced efficiency,” says Gurman Reen, Caterpillar sales manager for India. “Equipped with advanced engines, these new excavators deliver enhanced machine performance, boosting productivity while significantly improving fuel efficiency. Fuel consumption is now easily monitored via Cat Product Link™, enabling better operational insights. These machines feature three selectable work modes – Power, Smart and Eco – allowing operators to tailor performance to the task at hand and maximize fuel efficiency.”

Offering improved fuel efficiency, the Cat 3.6 engine powering the new Cat 321 and electrohydraulic system work together to help move material while using less fuel. Boom and stick regeneration circuits further reduce fuel consumption while improving cycle times. Reliable and durable, the 321 is built on proven components, and its strong X-structure lower frame carries loads from the excavators’ upper structure to the track.

Increased swing torque delivers seamless operation for the new Cat 322 while truck loading and trenching. Operators dig and lift from a stable platform created by its 4000 kg (8,820 lb) heavy-duty counterweight and eight-roller undercarriage. Powered by the efficient C3.6 engine, the 322 offers customers a choice between two robust undercarriage options – standard 4.1 m (13.4 ft) or medium 4.25 m (13.9 ft) – both built to withstand demanding applications. Increasing 322 versatility, the excavator design offers a choice of General Duty bucket options of 1.2 m3 (1.57 yd3) or 1.14 m3 (1.49 yd3) for earthmoving projects. For working in the quarry, the machine’s 1.1 m3 (1.44 yd3) Severe Duty bucket is engineered to provide long life handling rock, gravel and abrasive materials.

The new high-production 324 excavator moves more material in earthmoving applications with its large 1.4 m3 (1.83 yd3) General Duty bucket. A size-class exclusive, the 1.3 m3 (1.70 yd3) Severe Duty bucket enables the machine to be more productive for quarry applications. Supporting versatile, high-productivity performance across a range of demanding applications, the 324’s long, 4.45 m (14.6 ft) undercarriage delivers excellent stability. A 4550-kg (10,030-lb) heavy-duty counterweight and heavy-duty eight-roller undercarriage deliver a stable platform for digging and lifting.

Cat excavator design and manufacturing techniques, built on proven components, extend service intervals. Reinforced structures and upgraded carriages improve stability and durability for the new 321, 322 and 324. Reducing downtime, their sloped track frame helps prevent mud and debris accumulation, while the center track guiding guard helps keep the track aligned when traveling and working on slopes. Dissipating stress throughout the base of the excavator, a single-plate X-shaped box-section car body provides excellent resistance to torsional bending.

The latest single-plane cooling package reduces air resistance compared to traditional two-plane designs for better cooling performance and enhanced machine productivity. Equipped with an electrohydraulic control valve, pump and Engine Control Module, these next generation excavators provide smooth, precise operation in every pass with high fuel efficiency. The Positive Flow Control electrohydraulic system balances power with fuel efficiency and automatic engine speed control during no- or light-load conditions automatically reduces engine speed to minimize fuel consumption.

Operators quickly start the engine with a push button, and the new in-cab, high-resolution 203-mm (8-inch) touch screen monitor offers easy-to-use, intuitive operation. Continuously improved, the user interface provides intuitive navigation, minimizing performance interruption, and the low-effort joystick controls, offering customizable joystick patterns and preferences, which help the operator’s experience. Standard auto-hammer-stop protects tools from overheating and wear, increasing longevity.

Providing a quieter work environment, the new generation cab design features sound suppression, seals and viscous cab mounts to decrease noise and vibration. Standard automatic climate control helps to keep operators comfortable by maintaining a consistent cab temperature. Controls positioned in front of the operator help deliver comfortable machine control, while the adjustable seat offers three suspension levels and ergonomic design.

These new models are designed with safety and simplicity with a convenient work platform for routine service and maintenance items to be completed by technicians. Saving on maintenance costs, service intervals are extended and synchronized, while the first engine oil change interval is now increased to 500 hours. Five-hundred-hour Cat filters are designed to help smooth and contamination-free filtering. A standard electric priming pump reduces the risk of contamination by preventing unfiltered fuel from entering the fuel system, eliminating the need to manually prime the fuel system after filter changes.

The Cat cab design offers excellent visibility from the operator’s seat and includes two standard mirrors to keep operators aware of their surroundings. Customers can choose the optional rearview camera to further enhance visibility behind the excavator and an available ISO 15818:2017-compliant Rollover Protective Structure (ROPS) for additional operating safety. Further enhancing excavator servicing safety, a lockable disconnect switch isolates the battery to disconnect the electrical energy.

More information on the new Cat 321, 322 and 324 excavators can be found by contacting a Cat dealer or visiting cat.com.

# # #

About Caterpillar:

With 2024 sales and revenues of $64.8 billion, Caterpillar Inc. is the world’s leading manufacturer of construction and mining equipment, off-highway diesel and natural gas engines, industrial gas turbines and diesel-electric locomotives. For 100 years, we’ve been helping customers build a better, more sustainable world and are committed and contributing to a reduced-carbon future. Our innovative products and services, backed by our global dealer network, provide exceptional value that helps customers succeed. Caterpillar does business on every continent, principally operating through three primary segments – Construction Industries, Resource Industries and Energy & Transportation – and providing financing and related services through our Financial Products segment. Visit us at caterpillar.com or join the conversation on our social media channels at caterpillar.com/en/news/social-media.html.

Caterpillar rolls out products and services in each of its regions at different time intervals. Although every effort is made to ensure that product information is released only after Caterpillar has received confirmation from its independent dealer network, plants, and marketing subsidiaries that products and services are available in the relevant region, editors are kindly requested to verify with a Cat dealer for product availability and specifications.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow,” the “Power Edge” and Cat “Modern Hex” trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

VisionLink is a trademark of Caterpillar Inc., registered in the United States and in other countries.

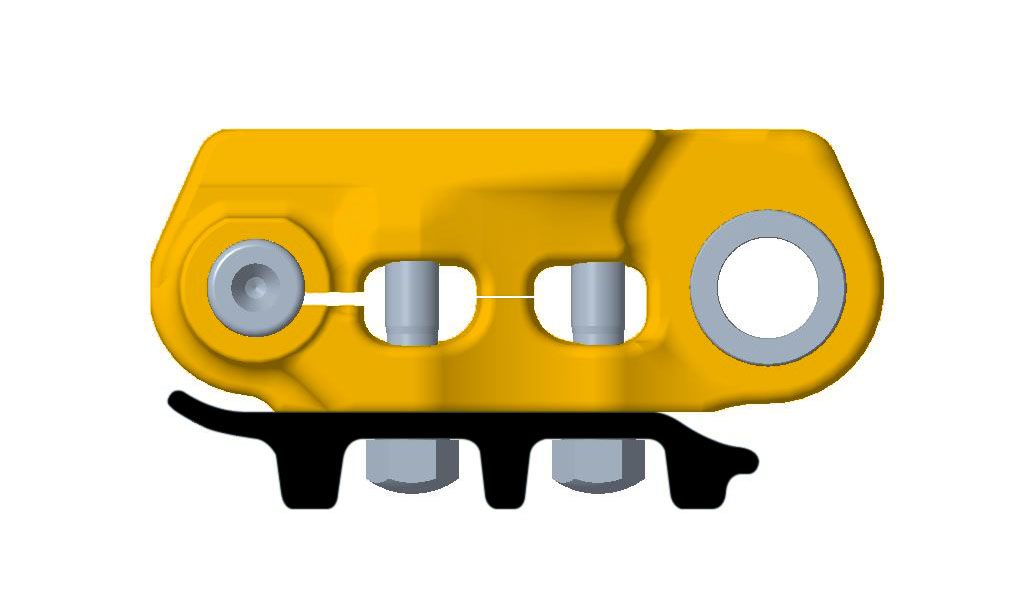

It’s all about getting back to work quicker with the new Cat® Track Clamp Master Link assembly, designed to improve track installation efficiency in the field by eliminating the need for a portable field press.

Learn MoreThe best machine operators across North America gathered in Clayton, NC to forge their legacy and prove their mastery of both equipment and technology.

Learn MoreCaterpillar is announcing its new Cat® 140 LVR Motor Grader, upgrading it to the next generation platform.

Learn MoreThe new heavy-duty Cat® 980 GC Wheel Loader offers low fuel consumption with an on-demand fan, load-sensing hydraulics, intuitive controls and Performance Series buckets.

Learn More