Pull-Down/Hoisting Capacity

| Pull-Down Capacity | Up to 39 009 kg (86,000 lb) Up to 39 009 kg (86,000 lb) |

Key Specs

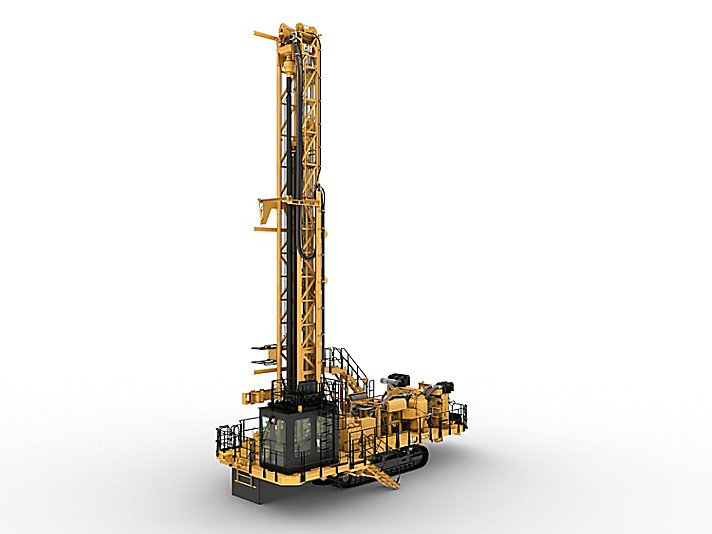

The Cat® MD6310 is a powerful, flexible rotary blasthole drill that offers a wide variety of features and options designed to meet your site’s specific needs and challenges. A world-class cab helps keep operators safe and comfortable while increasing performance. And it’s infused with the latest technologies that increase productivity and allow for autonomous drilling—improving the efficiency of all downstream operations. Designed to drill holes from 229-311 mm (9-12.25 in) in diameter, the MD6310 is is optimized for single-pass or multi-pass drilling in both rotary and down-the-hole drilling modes.

Achieve higher-quality collars and straighter holes that are more conducive to precision blasting

Improve your drilling efficiency and machine utilization with onboard Drill Assist tecnology

100% Cat components deliver reliable, long life and extended service intervals reduce downtime

| Pull-Down Capacity | Up to 39 009 kg (86,000 lb) Up to 39 009 kg (86,000 lb) |

| Hole Diameter | 229-311 mm (9-12.25 in) 229-311 mm (9-12.25 in) |

| Engine | Cat® C32B Cat® C32B |

| Bit Load | Up to 42 149 kg (Up to 92,922 lb) Up to 42 149 kg (Up to 92,922 lb) |

| Body Length - Standard Cab | 43.54 ft 13.27 m |

| Length - Mast Down - Extended Cab | 83.33 ft 25.43 m |

| Length - Mast Down - Standard Cab | 81.69 ft 24.9 m |

| Width - Front | 17.68 ft 5.39 m |

| Body Length - Extended Cab | 42.24 ft 13.79 m |

| Height - Mast Up | 77.99 ft 23.77 m |

| Width - Rear | 20.73 ft 6.32 m |

| 13.7 m (44.9 ft) Mast - Hoist Speed | 122.7 ft/min 37.4 m/min |

| 17.5 m (57.4 ft) Mast - Hoist Speed | 122.7 ft/min 37.4 m/min |

| Emissions (Equivalent to Tier 2): Engine | C32B @ 1,800 rpm C32B @ 1,800 rpm |

| 13.7 m (44.9 ft) Mast - Hole Diameter Range 203-311 mm (8-12.25 in) - Multi Pass Depth | Down to 74.6 m (Down to 244.9 ft) Down to 74.6 m (Down to 244.9 ft) |

| 17.5 m (57.4 ft) Mast - Hole Diameter Range 203-311 mm (8-12.25 in) - Multi Pass Depth | Down to 47.9 m (Down to 157.4 ft) Down to 47.9 m (Down to 157.4 ft) |

| 17.5 m (57.4 ft) Mast - Pulldown Capacity | Up to 39 009 kg (Up to 86,000 lb) Up to 39 009 kg (Up to 86,000 lb) |

| 17.5 m (57.4 ft) Mast - Hole Diameter Range 203-311 mm (8-12.25 in) - Single Pass Depth | 57.4 ft 17.5 m |

| 13.7 m (44.9 ft) Mast - Hole Diameter Range | 203-311 mm (8-12.25 in) 203-311 mm (8-12.25 in) |

| Angle Drilling | Vertical to 30° (in 5° increments) Vertical to 30° (in 5° increments) |

| 17.5 m (57.4 ft) Mast - Hole Diameter Range | 203-311 mm (8-12.25 in) 203-311 mm (8-12.25 in) |

| 17.5 m (57.4 ft) Mast - Bit Load - Single Pass | Up to 42 149 kg (Up to 92,922 lb) Up to 42 149 kg (Up to 92,922 lb) |

| 13.7 m (44.9 ft) Mast - Hoist Capacity | Up to 22 113 kg (Up to 48,750 lb) Up to 22 113 kg (Up to 48,750 lb) |

| Compressor - Rotary Drilling (1) | 56.6 m³/min (2,000 ft³/min) @ 8.6 bar (125 psi) 56.6 m³/min (2,000 ft³/min) @ 8.6 bar (125 psi) |

| Compressor - Rotary Drilling (2) | 73.6 m³/min (2,600 ft³/min) @ 7.6 bar (110 psi) 73.6 m³/min (2,600 ft³/min) @ 7.6 bar (110 psi) |

| 13.7 m (44.9 ft) Mast - Pulldown Capacity | Up to 39 009 kg (Up to 86,000 lb) Up to 39 009 kg (Up to 86,000 lb) |

| 13.7 m (44.9 ft) Mast - Hole Diameter Range 203-311 mm (8-12.25 in) - Single Pass Depth | 44.9 ft 13.7 m |

| Emissions (U.S. EPA Tier 4 Final): Engine | C32B @ 1,800 rpm C32B @ 1,800 rpm |

| Compressor - DTH Drilling | 42.2 m³/min (1,500 ft³/min) @ 34.4 bar (500 psi) 42.2 m³/min (1,500 ft³/min) @ 34.4 bar (500 psi) |

| 17.5 m (57.4 ft) Mast - Hoist Capacity | Up to 22 113 kg (Up to 48,750 lb) Up to 22 113 kg (Up to 48,750 lb) |

| 13.7 m (44.9 ft) Mast - Bit Load - Single Pass | Up to 41 165 kg (Up to 90,753 lb) Up to 41 165 kg (Up to 90,753 lb) |

| Emissions (U.S. EPA Tier 4 Final): Power Rating ISO 14396 | 1007 hp 751 kW |

| Emissions (Equivalent to Tier 2): Power Rating ISO 14396 | 1031 hp 769 kW |

| Drawbar Pull | 122971 lbf 547000 N |

| Track chain guards and guides | Level two Level two |

| Travel Speed | 1.5 mile/h 2.45 km/h |

| Lower rollers | Fourteen (14) Fourteen (14) |

| Model | Cat® 349E EL Excavator type Cat® 349E EL Excavator type |

| Carrier Rollers | Three (3) Three (3) |

| Triple grousers for soft rock ground bearing pressure 1.28 bar (18.5 psi) | 29.5 in 750 mm |

| Components (10) | In-deck mounted battery box In-deck mounted battery box |

| Components (9) | Self-closing, gates secure egress ladder locations Self-closing, gates secure egress ladder locations |

| Components (12) | Air hose retention devices Air hose retention devices |

| Components (2) | Seven (7) engine shut down buttons: in cab, at drill deck, on deck at power train, ground accessible by main access point and each side of the drill front and left Seven (7) engine shut down buttons: in cab, at drill deck, on deck at power train, ground accessible by main access point and each side of the drill front and left |

| Components (6) | Guards for exhaust pipes and turbo lines Guards for exhaust pipes and turbo lines |

| Feature | Approach angle of 14 degrees facilitates loading and unloading on a lowboy Approach angle of 14 degrees facilitates loading and unloading on a lowboy |

| Components (7) | Mast access ladder with mast grating (option) Mast access ladder with mast grating (option) |

| Components (4) | Tram alarm is automatic and audible Tram alarm is automatic and audible |

| Components (11) | Ground level keyed battery disconnect/starter lockout with remote jump start terminals Ground level keyed battery disconnect/starter lockout with remote jump start terminals |

| Components (1) | Alloy drill deck covers, with storage provision Alloy drill deck covers, with storage provision |

| Components (5) | Hinged protective guard for full front drill window Hinged protective guard for full front drill window |

| Components (3) | Electric horn activated by push button in the cab Electric horn activated by push button in the cab |

| Components (8) | Three egress points on deck areas in addition to main access Three egress points on deck areas in addition to main access |

| Components (10) | Filter indicators for hydraulic, compressor and engine Filter indicators for hydraulic, compressor and engine |

| Components (14) | ECM controlled proportional fan speed control system ECM controlled proportional fan speed control system |

| Components (23) | Data logging of machine health with warnings, and fault code records; export capability Data logging of machine health with warnings, and fault code records; export capability |

| Components (20) | Cabin pressure manometer with indicator (option) Cabin pressure manometer with indicator (option) |

| Components (3) | Rotation torque control Rotation torque control |

| Components (12) | Dust suppression control Dust suppression control |

| Components (17) | Tram interlock, mast up and locked or down and parked Tram interlock, mast up and locked or down and parked |

| Components (1) | All electric controls for drilling, tramming, leveling plus auxiliary functions All electric controls for drilling, tramming, leveling plus auxiliary functions |

| Components (22) | Prewired for Terrain and autonomous operation Prewired for Terrain and autonomous operation |

| Components (8) | Delayed engine shut down Delayed engine shut down |

| Components (19) | Cab environment controls (AC, filter, heat, fan speeds) Cab environment controls (AC, filter, heat, fan speeds) |

| Components (7) | Drill performance and display system Drill performance and display system |

| Components (13) | Mast lock indicator Mast lock indicator |

| Components (6) | Drill depth meter Drill depth meter |

| Components (2) | Electronic compressor control Electronic compressor control |

| Components (4) | Virtual rotary head travel stops and interlocks Virtual rotary head travel stops and interlocks |

| Components (11) | Jack pressure sensors in the display Jack pressure sensors in the display |

| Components (5) | Pipe positioner engaged/disengaged indicator Pipe positioner engaged/disengaged indicator |

| Components (18) | Tram interlock, jacks retracted Tram interlock, jacks retracted |

| Components (16) | Tram interlock, pipe in hole Tram interlock, pipe in hole |

| Components (21) | Dust curtain lifting system – auto hydraulic raise front and rear (option) Dust curtain lifting system – auto hydraulic raise front and rear (option) |

| Components (15) | Tram interlock, machine stability limits Tram interlock, machine stability limits |

| Components (9) | Rotary head rpm gauge – (digital display in screen) Rotary head rpm gauge – (digital display in screen) |

| Body Length - Standard Cab | 43.54 ft 13.27 m |

| Body Length - Extended Cab | 42.24 ft 13.79 m |

| Width - Rear | 20.74 ft 6.32 m |

| Length - Mast Down - Standard Cab | 69.23 ft 21.1 m |

| Length - Mast Down - Extended Cab | 70.87 ft 21.62 m |

| Height - Mast Up | 65.39 ft 19.93 m |

| Width - Front | 17.68 ft 5.39 m |

| Note (2) | Configuration choices include single pass, multi pass, vertical out to 30 degree angle drilling Configuration choices include single pass, multi pass, vertical out to 30 degree angle drilling |

| Features (12) | Pipe catcher; manual or optional hydraulically actuated Pipe catcher; manual or optional hydraulically actuated |

| Features (4) | Feed system accommodates multiple pipe diameters Feed system accommodates multiple pipe diameters |

| Note (1) | Hydraulic, indexing pipe carousels accept various pipe diameters Hydraulic, indexing pipe carousels accept various pipe diameters |

| Features (13) | Tool oiler 113.5 L (30 gal) oil injection system (Rotary drilling only) Tool oiler 113.5 L (30 gal) oil injection system (Rotary drilling only) |

| Features (2) | Pulldown/hoist system is a single cylinder Pulldown/hoist system is a single cylinder |

| Features (1) | 13.7 m (44.9 ft) or 17.5 m (57.4 ft) Mast configurations complete with pipe rack carousel 13.7 m (44.9 ft) or 17.5 m (57.4 ft) Mast configurations complete with pipe rack carousel |

| Features (9) | Drill pipe positioner Drill pipe positioner |

| Features (10) | Overhead winch with remote; variable speed drive with ≥ 1818 kg (4,000 lb) rating, length to reach 6.1 m (20 ft) past drill deck (option) Overhead winch with remote; variable speed drive with ≥ 1818 kg (4,000 lb) rating, length to reach 6.1 m (20 ft) past drill deck (option) |

| Features (3) | Auto tensioning of pull down and hoist cables Auto tensioning of pull down and hoist cables |

| Features (6) | Sliding deck wrench assembly Sliding deck wrench assembly |

| Features (11) | Rotation Gear Box with dual motor arrangement, up to 160 rpm, and 16,000 N∙m of torque (11,800 ft-lb) Rotation Gear Box with dual motor arrangement, up to 160 rpm, and 16,000 N∙m of torque (11,800 ft-lb) |

| Features (15) | Mast access ladder and grating (option) Mast access ladder and grating (option) |

| Features (5) | Variable grip hydraulic break out wrench (HOBO) for range of pipe diameters Variable grip hydraulic break out wrench (HOBO) for range of pipe diameters |

| Features (7) | Configured with roller deck bushing for tricone applications, two-piece deck bushing for DTH Configured with roller deck bushing for tricone applications, two-piece deck bushing for DTH |

| Features (14) | Mast lanyard mounting provisions (option) Mast lanyard mounting provisions (option) |

| Features (8) | Angle drilling 0-30°; in 5° increments Angle drilling 0-30°; in 5° increments |

| Components (4) | Ether starting aid; ether bottle supplied locally Ether starting aid; ether bottle supplied locally |

| Components (2) | Scheduled oil sampling (S∙O∙SSM) ports Scheduled oil sampling (S∙O∙SSM) ports |

| Components (1) | Dual starter motors Dual starter motors |

| Components (3) | Common air intake filters provide +500 hour service interval in normal operating conditions Common air intake filters provide +500 hour service interval in normal operating conditions |

| Package (1) | Basic/Manual – Centralized Manual Lube; Gravity Fill for fuel and water Basic/Manual – Centralized Manual Lube; Gravity Fill for fuel and water |

| Package (2) | Standard – Fast Fill for fuel and water; Automatic Lubrication System Standard – Fast Fill for fuel and water; Automatic Lubrication System |

| Package (3) | Premium – Service center for lubricant drain and fill (compressor oil, hydraulic oil, gearbox oil, engine oil, tool lubrication and grease), Automatic Lubrication System, Fast Fill for fuel and water, blowdown hose Premium – Service center for lubricant drain and fill (compressor oil, hydraulic oil, gearbox oil, engine oil, tool lubrication and grease), Automatic Lubrication System, Fast Fill for fuel and water, blowdown hose |

| Water injection and dry dust collector (option) |

– Water tank capacity 1514 L (400 gal) – 204 m³/min (7,200 cfm) dry dust collector – Self-cleaning filters, with auto-eject dust chute – Water tank capacity 1514 L (400 gal) – 204 m³/min (7,200 cfm) dry dust collector – Self-cleaning filters, with auto-eject dust chute |

| Water Injection - Standard | – Water tank capacity 1514 L (400 gal) – Water tank capacity 1514 L (400 gal) |

| Choices (1) | Dust curtain hydraulic lifters raise front and rear dust curtains (option) (recommended with dust collector) Dust curtain hydraulic lifters raise front and rear dust curtains (option) (recommended with dust collector) |

| Choices (3) | Static dust curtains, four sides boxed in (standard) Static dust curtains, four sides boxed in (standard) |

| High Volume Water Injection System - Not Compatible with Basic Service Package |

– Water tanks total capacity 3785 L (1,000 gal) maximum – Primary tank above deck – 1514 L (400 gal) capacity (heated for extreme cold weather) – Secondary tank above deck – 2271 L (600 gal) capacity deck – Water tanks total capacity 3785 L (1,000 gal) maximum – Primary tank above deck – 1514 L (400 gal) capacity (heated for extreme cold weather) – Secondary tank above deck – 2271 L (600 gal) capacity deck |

| Choices (2) | Tram off spray to wet the ground around the cuttings pile (not recommended for cold weather applications) Tram off spray to wet the ground around the cuttings pile (not recommended for cold weather applications) |

| Components (4) | Top Sub, or Shock sub and cross over adapter (option) Top Sub, or Shock sub and cross over adapter (option) |

| Components (3) | Deck wrench, sliding Deck wrench, sliding |

| Components (5) | Bit sub Bit sub |

| Components (1) | Roller deck bushing Roller deck bushing |

| Components (6) | Pipe wiper seal Pipe wiper seal |

| Components (2) | Pipe positioner inserts Pipe positioner inserts |

| Rotary Drilling (2) | 73.6 m³/min (2,600 ft³/min) @ 7.6 bar (110 psi) 73.6 m³/min (2,600 ft³/min) @ 7.6 bar (110 psi) |

| Receiver Tank Choice (1) | Low pressure 8.6 bar (125 psi) for ASME/CR N/AU or CE Low pressure 8.6 bar (125 psi) for ASME/CR N/AU or CE |

| Rotary Drilling (1) | 56.6 m³/min (2,000 ft³/min) @ 8.6 bar (125 psi) 56.6 m³/min (2,000 ft³/min) @ 8.6 bar (125 psi) |

| DTH Drilling - Includes Tool Lubrication and Hammer Storage | 42.2 m³/min (1,500 ft³/min) @ 34.4 bar (500 psi) 42.2 m³/min (1,500 ft³/min) @ 34.4 bar (500 psi) |

| Note |

With the compressors variable volume control, the operator can limit air output resulting in reduced fuel consumption – Both high and low pressure compressors contain this feature With the compressors variable volume control, the operator can limit air output resulting in reduced fuel consumption – Both high and low pressure compressors contain this feature |

| Receiver Tank Choice (2) | High pressure 34.4 bar (500 psi) for ASME/CR N/AU or CE High pressure 34.4 bar (500 psi) for ASME/CR N/AU or CE |

| Choice | Electronic compressor control and regulation with purged air lines Electronic compressor control and regulation with purged air lines |

| Components (5) | Four (4) lift lugs, for use with cables or chains Four (4) lift lugs, for use with cables or chains |

| Components (7) | Bit storage box in-deck with hinged cover (option) Bit storage box in-deck with hinged cover (option) |

| Components (6) | Walkway around cab to drill deck (option) Walkway around cab to drill deck (option) |

| Features (2) | Slip resistant surface Slip resistant surface |

| Features (3) | Fuel tank capacity 1609 L (425 gal) Fuel tank capacity 1609 L (425 gal) |

| Components (1) | Stationary rear deck; for vertical and angle drilling Stationary rear deck; for vertical and angle drilling |

| Components (2) | Four leveling jacks to provide leveling on a 7° bench (any orientation) Four leveling jacks to provide leveling on a 7° bench (any orientation) |

| Features (6) | Three egress points on deck areas in addition to main access Three egress points on deck areas in addition to main access |

| Components (10) | Drill pipe thread greaser with remote fill tank or disposable grease bucket (option) Drill pipe thread greaser with remote fill tank or disposable grease bucket (option) |

| Features (7) | Sturdy guardrails, toe guards, self closing gates Sturdy guardrails, toe guards, self closing gates |

| Components (4) | Heavy duty tow hooks (front end) Heavy duty tow hooks (front end) |

| Components (3) | Manual, centralized, lubrication banks for all pivot points on drill, or automated lubrication system (option) Manual, centralized, lubrication banks for all pivot points on drill, or automated lubrication system (option) |

| Components (8) | DTH hammer storage on drill deck with high pressure configuration (option) DTH hammer storage on drill deck with high pressure configuration (option) |

| Features (4) | Fuel capacity expansion for additional +1609 L (425 gal) Fuel capacity expansion for additional +1609 L (425 gal) |

| Features (5) | Bolt-on platform for cold weather generator or fire suppression bottles (option) Bolt-on platform for cold weather generator or fire suppression bottles (option) |

| Components (9) | Hydraulically operated viewing hatch in drill deck with spotlight (option) Hydraulically operated viewing hatch in drill deck with spotlight (option) |

| Features (1) | Jacks, mast pivot and deck are welded integrally to mainframe for maximum durability and long life Jacks, mast pivot and deck are welded integrally to mainframe for maximum durability and long life |

| Components (2) | Separate engine cooling module Separate engine cooling module |

| Components (1) | Coolers with easy cleaning access Coolers with easy cleaning access |

| Components (3) | Replaceable cooler core sections Replaceable cooler core sections |

| Components (4) | Automatic variable speed fan control Automatic variable speed fan control |

| Features | Functional in ambient temperature of 52° C (125° F) Functional in ambient temperature of 52° C (125° F) |

| Components (6) | Wiring for third party interface Wiring for third party interface |

| Components (3) | Drill assist (single or multipass auto drill) (options) Drill assist (single or multipass auto drill) (options) |

| Components (5) | Optional Command for Drilling enables each operator to manage more than one machine Optional Command for Drilling enables each operator to manage more than one machine |

| Type | Autonomy ready Autonomy ready |

| Components (2) | Auto level, auto retract, auto mast Auto level, auto retract, auto mast |

| Components (1) | Drill depth indicator and interlocks Drill depth indicator and interlocks |

| Optional Cat Terrain for Drills - Mining System Interface |

– Production – Navigation – Production – Navigation |

| Components (4) | Product Link Elite (hardware from factory, subscription package via dealer) Product Link Elite (hardware from factory, subscription package via dealer) |

| 7.62 m (25 ft) pipes - pipe rack carousel holds a quantity of four or five pipes, 17.5 m (57.4 ft) Mast: Rotary (1) | 8 in 203 mm |

| 7.62 m (25 ft) pipes - pipe rack carousel holds a quantity of four or five pipes, 17.5 m (57.4 ft) Mast: DTH | 7 in 178 mm |

| 7.62 m (25 ft) pipes - pipe rack carousel holds a quantity of four or five pipes, 17.5 m (57.4 ft) Mast: Rotary or DTH | 7.625 in 194 mm |

| 7.62 m (25 ft) pipes - pipe rack carousel holds a quantity of four or five pipes, 17.5 m (57.4 ft) Mast: Rotary (2) | 8.625 in 219 mm |

| 7.62 m (25 ft) pipes - pipe rack carousel holds a quantity of four or five pipes, 17.5 m (57.4 ft) Mast: Rotary | 9.25 in 235 mm |

| 12.19 m (40 ft) pipes - pipe rack carousel holds a quantity of four (4) or five (5) pipes, 13.7 m (44.9 ft) Mast: Rotary (2) | 8.625 in 219 mm |

| 12.19 m (40 ft) pipes - pipe rack carousel holds a quantity of four (4) or five (5) pipes, 13.7 m (44.9 ft) Mast: Rotary (1) | 8 in 203 mm |

| 12.19 m (40 ft) pipes - pipe rack carousel holds a quantity of four (4) or five (5) pipes, 13.7 m (44.9 ft) Mast: DTH | 7 in 178 mm |

| 12.19 m (40 ft) pipes - pipe rack carousel holds a quantity of four (4) or five (5) pipes, 13.7 m (44.9 ft) Mast: Rotary or DTH | 7.625 in 194 mm |

| Note |

Dual purpose carousel pipe: 13.7 m (44.9 ft) Mast; holds quantity of two (2) 12.19 m (40 ft) pipes and quantity of two (2) 9.14 m (30 ft) pipes, and adapters to connect to DTH hammer and tricone bit (DTH hammer and tricone not included)

|

| Climate Level 2 Arctic Fluids and Lubricants | Rated down to –18° C (–0.4° F) temperatures Rated down to –18° C (–0.4° F) temperatures |

| Climate Level 1 Standard Fluids and Lubricants (1) | Rated down to –1° C (30° F) temperatures Rated down to –1° C (30° F) temperatures |

| Climate Level 1 Standard Fluids and Lubricants (2) | Withstands high heat to 52° C (125° F) Withstands high heat to 52° C (125° F) |

| Climate Level 4 Arctic Fluids and Lubricants, Heating Package (6) | Breaker panel includes five (5) additional breakers for locally supplied heating elements, if needed Breaker panel includes five (5) additional breakers for locally supplied heating elements, if needed |

| Climate Level 4 Arctic Fluids and Lubricants, Heating Package (3) | Full arctic lubricant package includes: engine oil, compressor oil and hydraulic oil Full arctic lubricant package includes: engine oil, compressor oil and hydraulic oil |

| Climate Level 4 Arctic Fluids and Lubricants, Heating Package (1) | Rated down to –40° C (–40° F) temperatures Rated down to –40° C (–40° F) temperatures |

| Climate Level 4 Arctic Fluids and Lubricants, Heating Package (5) | Shore power connection box with switchable 240-600V (50 amp) connection; diesel genset and or plug, sold separately Shore power connection box with switchable 240-600V (50 amp) connection; diesel genset and or plug, sold separately |

| Climate Level 4 Arctic Fluids and Lubricants, Heating Package (2) | Diesel fired heating system that heats and circulates engine coolant through the: engine block, primary water tank, heating elements for battery trays with a provision for fuel tanks Diesel fired heating system that heats and circulates engine coolant through the: engine block, primary water tank, heating elements for battery trays with a provision for fuel tanks |

| Climate Level 4 Arctic Fluids and Lubricants, Heating Package (4) | Electric heating package with breaker panel to power: 120V heating blanket for compressor receiver tank, compressor control box, heat trace for compressor control lines, heat trace for housing from water tank to water pump and water fast-fill assembly plus tank Electric heating package with breaker panel to power: 120V heating blanket for compressor receiver tank, compressor control box, heat trace for compressor control lines, heat trace for housing from water tank to water pump and water fast-fill assembly plus tank |

| Cable Diameter | 0.5 in 13 mm |

| Winch Reach - Past The Drill Deck | 20 ft 6.1 m |

| Capacity Rating | 4000 lb 1814 kg |

| Note | Variable speed control Variable speed control |

| Lighting |

– LED interior lights; separate reading light, and backlit joysticks and keypads – Zone controls for area lights and spot lighting for night drilling – Flood lights for the drill perimeter – Spot lights for power group area; drill deck; mast carousel; access ladder and walkways – Standard lighting is Halogen, 1,300 lumens flood light on perimeter, area spot lights have 1,950 lumens – Premium lighting is LED, 4,200 lumens flood light on perimeter (option) – Mast clearance lights, cab mounted strobe, front mounted tram beacon (option) – LED interior lights; separate reading light, and backlit joysticks and keypads – Zone controls for area lights and spot lighting for night drilling – Flood lights for the drill perimeter – Spot lights for power group area; drill deck; mast carousel; access ladder and walkways – Standard lighting is Halogen, 1,300 lumens flood light on perimeter, area spot lights have 1,950 lumens – Premium lighting is LED, 4,200 lumens flood light on perimeter (option) – Mast clearance lights, cab mounted strobe, front mounted tram beacon (option) |

| Components (7) | Operator station design integrates an ergonomic seat, armchair joystick controls with full instrumentation, and two 254 mm (10 in) color, high definition touchscreens and 12 volt power port Operator station design integrates an ergonomic seat, armchair joystick controls with full instrumentation, and two 254 mm (10 in) color, high definition touchscreens and 12 volt power port |

| Components (4) | Drill performance touchscreen display Drill performance touchscreen display |

| Components (3) | Cab perimeter walkway available for both cab sizes Cab perimeter walkway available for both cab sizes |

| Components (1) | Spacious FOPS cab has 3 m² (32.4 ft²) floor space with an integrated operator station Spacious FOPS cab has 3 m² (32.4 ft²) floor space with an integrated operator station |

| Components (13) | Seat swivels, locks and has two point/76 mm (3 in) seat belt, tilts (5° adjustment), lumbar support, fore/aft seat adjustment 80 mm (3.1 in) Seat swivels, locks and has two point/76 mm (3 in) seat belt, tilts (5° adjustment), lumbar support, fore/aft seat adjustment 80 mm (3.1 in) |

| Components (9) | Power convertor 24V to 12V Power convertor 24V to 12V |

| Components (2) | Extended cab option 4.2 m² (45.2 ft²); prewired and dedicated space for refrigerator and microwave Extended cab option 4.2 m² (45.2 ft²); prewired and dedicated space for refrigerator and microwave |

| HVAC |

– Floor vents in the foot rest area – Roof-mounted air conditioner/heating/pressurizing unit – Filter access from deck, does not require roof access, and has approximately 500 hour service interval – Defogging HVAC vents on driller window – Floor vents in the foot rest area – Roof-mounted air conditioner/heating/pressurizing unit – Filter access from deck, does not require roof access, and has approximately 500 hour service interval – Defogging HVAC vents on driller window |

| Components (6) | Two swing-out hinged doors with windows and Cat keyed locks Two swing-out hinged doors with windows and Cat keyed locks |

| Components (14) | Trainer’s seat that folds away and has retractable seat belt (optional) Trainer’s seat that folds away and has retractable seat belt (optional) |

| Cameras |

– Mounted on the front and left sides to provide 360° view from operator's seat – Camera on the mast to view pipe carousel/top drive operation – Mounted on the front and left sides to provide 360° view from operator's seat – Camera on the mast to view pipe carousel/top drive operation |

| Components (5) | Cab rubber shock-mounts absorb mechanical vibration and restrict exterior noise Cab rubber shock-mounts absorb mechanical vibration and restrict exterior noise |

| Components (10) | Radio-ready for communication and entertainment radio Radio-ready for communication and entertainment radio |

| Cab - Premium |

– Leather seat with heat and ventilation – Dual pane window glass – Front window guard – Additional in-cab storage box – Additional windshield wipers on front and rear windows – Window shades (option) – Foldaway trainer’s seat (option) – Removable floor mat – Leather seat with heat and ventilation – Dual pane window glass – Front window guard – Additional in-cab storage box – Additional windshield wipers on front and rear windows – Window shades (option) – Foldaway trainer’s seat (option) – Removable floor mat |

| Components (11) | Cab roof access ladder (option) Cab roof access ladder (option) |

| Cab - Standard |

– Fabric seat – Single pane window glass – Windshield wiper for driller window – Window shades (option) – Foldaway trainer’s seat (option) – Removable floor mat – Fabric seat – Single pane window glass – Windshield wiper for driller window – Window shades (option) – Foldaway trainer’s seat (option) – Removable floor mat |

| Components (8) | Additional display screen for cc cameras; color, high-definition 254 mm (10 in) Additional display screen for cc cameras; color, high-definition 254 mm (10 in) |

| Components (12) | Literature holder Literature holder |

| Components (4) | Virtual rotary head travel stops and interlocks Virtual rotary head travel stops and interlocks |

| Components (3) | Rotary torque control Rotary torque control |

| Components (2) | Rotation gear box with dual motor arrangement, up to 160 rpm, and 16 000 N∙m (11,800 lbf-ft) of torque Rotation gear box with dual motor arrangement, up to 160 rpm, and 16 000 N∙m (11,800 lbf-ft) of torque |

| Components (1) | Spindle with 168 mm (6.625 in) API regular thread and splined collar Spindle with 168 mm (6.625 in) API regular thread and splined collar |

| Components (2) | One (1) auxiliary circuit pump – 110 cc (piston, load sensing) One (1) auxiliary circuit pump – 110 cc (piston, load sensing) |

| Components (3) | Two (2) fan pumps – 1,000 cc (piston, with proportional electronic controls) Two (2) fan pumps – 1,000 cc (piston, with proportional electronic controls) |

| Components (1) | Two (2) primary pumps – 210 cc (piston, with proportional electronic controls) Two (2) primary pumps – 210 cc (piston, with proportional electronic controls) |

| Components (4) | Two (2) charge pumps – 43.9 + 56.5 cc (double stack gear, fixed displacement) Two (2) charge pumps – 43.9 + 56.5 cc (double stack gear, fixed displacement) |

| Components (5) | Scheduled Oil Sampling (S∙O∙S) ports Scheduled Oil Sampling (S∙O∙S) ports |

| Components (1) | Two piece bushing Two piece bushing |

| Components (6) | Pipe wiper seal Pipe wiper seal |

| Components (4) | Shock sub and top sub adapter Shock sub and top sub adapter |

| Components (5) | Cross over hammer adapter Cross over hammer adapter |

| Components (3) | Deck wrench, sliding Deck wrench, sliding |

| Components (2) | Pipe positioner inserts Pipe positioner inserts |

| Choice (1) | Fixed access ladder to the cab area Fixed access ladder to the cab area |

| Choice (2) | Cascading, hydraulic stairs to cab area (option) – includes jack and tram interlock that activates when the stairs are down Cascading, hydraulic stairs to cab area (option) – includes jack and tram interlock that activates when the stairs are down |

| Choice (3) | Cab perimeter walkway available with either choice Cab perimeter walkway available with either choice |

| Mast Accessories Hydraulic (2) | One hydraulic pipe catcher, plus one wire rope, hydraulically actuated pipe positioner, hydraulic bit basket One hydraulic pipe catcher, plus one wire rope, hydraulically actuated pipe positioner, hydraulic bit basket |

| Mast Accessories Hydraulic (1) | One hydraulic pipe catcher, hydraulically actuated pipe positioner, hydraulic bit basket One hydraulic pipe catcher, hydraulically actuated pipe positioner, hydraulic bit basket |

| Angle Drilling | Included with either mast Included with either mast |

| Mast Accessories Manual, 17.5 m (57.4 ft) Mast | Two wire rope pipe catchers, hydraulically actuated pipe positioner, manual bit basket Two wire rope pipe catchers, hydraulically actuated pipe positioner, manual bit basket |

| Mast Accessories Manual, 13.7 m (44.9 ft) Mast | One wire rope pipe catcher, hydraulically actuated pipe positioner, manual bit basket One wire rope pipe catcher, hydraulically actuated pipe positioner, manual bit basket |

| 13.7 m (44.9 ft) Mast Carousel; holds quantity of 4 × 12.19 m (40 ft) pipes; total depth 62.5 m (204.9 ft): Pipe diameters | 178 mm (7 in), 194 mm (7.625 in), 203 mm (8 in), 219 mm (8.625 in) 178 mm (7 in), 194 mm (7.625 in), 203 mm (8 in), 219 mm (8.625 in) |

| 13.7 m (44.9 ft) Mast Carousel; holds quantity of 5 × 12.19 m (40 ft) pipes; total depth 74.6 m (244.9 ft): Pipe diameters | 194 mm (7.625 in), 219 mm (8.625 in) 194 mm (7.625 in), 219 mm (8.625 in) |

| 17.5 m (57.4 ft) Mast Carousel; holds quantity of 2 × 7.62 m (25 ft) pipes; total depth 32.7 m (107.4 ft): Pipe diameter | 9.25 in 235 mm |

| 17.5 m (57.4 ft) Mast Carousel; holds quantity of 4 × 7.62 m (25 ft) pipes; total depth 48 m (157.5 ft): Pipe diameters | 178 mm (7 in), 194 mm (7.625 in), 203 mm (8 in), 219 mm (8.625 in) 178 mm (7 in), 194 mm (7.625 in), 203 mm (8 in), 219 mm (8.625 in) |

| Note |

13.7 m (44.9 ft) Mast Carousel, dual purpose; holds quantity of two (2) 12.19 m (40 ft) pipes and quantity of two (2) 9.14 m (30 ft) pipes, and adapters to connect to DTH hammer and tricone bit (DTH hammer and tricone not included)

|

| Option | Bushing Retention Tool 178 to 235 mm (7.00 to 9.25 in) pipe diameter Bushing Retention Tool 178 to 235 mm (7.00 to 9.25 in) pipe diameter |

| Lifting Bails (Available on Request) |

– 114 mm (4.5 in) API reg thread – 140 mm (5.5 in) API reg thread – 168 mm (6.625 in) for top sub/shock sub API thread – 114 mm (4.5 in) for 178 mm (7 in) pipe BECO thread – 152 mm (6 in) for 194 mm (7.625 in) up to 235 mm (9.25 in) pipe BECO thread – 114 mm (4.5 in) API reg thread – 140 mm (5.5 in) API reg thread – 168 mm (6.625 in) for top sub/shock sub API thread – 114 mm (4.5 in) for 178 mm (7 in) pipe BECO thread – 152 mm (6 in) for 194 mm (7.625 in) up to 235 mm (9.25 in) pipe BECO thread |

| Working Weight Range - Minimum/Maximum | 75 800/97 000 kg (167,110/213,848 lb) 75 800/97 000 kg (167,110/213,848 lb) |

| Variable Grip Hydraulic Break Out Wrench Grip Ranges (2) | 235 mm (9.25 in) 235 mm (9.25 in) |

| Variable Grip Hydraulic Break Out Wrench Grip Ranges (1) | 178-219 mm (7.0-8.625 in) 178-219 mm (7.0-8.625 in) |

| Working Weight Range - Minimum/Maximum | 75 500/97 500 kg (166,449/214,950 lb) 75 500/97 500 kg (166,449/214,950 lb) |

Leverage Caterpillar connected data and security principles to improve efficiencies, increase productivity and make your business more profitable.

Cat® MineStar™ Command for drilling delivers cost-effective, high precision drilling through automation — which will ultimately reduce operating costs, increase safety and improve productivity. Command for drilling ensures that every hole is accurately placed, drilled to the proper elevation and angle, and able to stand up until blasting. A range of capabilities lets site managers configure and automate the drilling system to their budgets and needs. From predrill planning to blasting, Command impacts the bottom line all the way through the crusher and mill.

Cat® MineStar™ Command for drilling delivers cost-effective, high precision drilling through automation — which will ultimately reduce operating costs, increase safety and improve productivity. Command for drilling ensures that every hole is accurately placed, drilled to the proper elevation and angle, and able to stand up until blasting. A range of capabilities lets site managers configure and automate the drilling system to their budgets and needs. From predrill planning to blasting, Command impacts the bottom line all the way through the crusher and mill.

Cat® MineStar Fleet is the single best source for fleet management information. An integrated fleet monitoring and management system, it can be used with any machine or system to measure, manage and maximize every facet of an operation, no matter the size or type. Fleet provides real-time visibility to cycle time, payload and other key operational parameters. It monitors machine locations and material movement and provides alerts of misroutes to ensure material is moved to the proper location.

Cat® MineStar Fleet is the single best source for fleet management information. An integrated fleet monitoring and management system, it can be used with any machine or system to measure, manage and maximize every facet of an operation, no matter the size or type. Fleet provides real-time visibility to cycle time, payload and other key operational parameters. It monitors machine locations and material movement and provides alerts of misroutes to ensure material is moved to the proper location.

Through regular monitoring of machine conditions, mines can adopt a more proactive approach to maintenance and repair. Equipment health data is a key contributor to that approach. Data helps mines identify equipment problems long before failure.

Accessing the right data at the right time is critical to improving operational intelligence and machine predictive analysis. Cat® MineStar™ Health helps you meet that need by connecting you to your machines and delivering that important information. The MineStar Health portfolio set consists of Connectivity Enablers that collect, convert and transmit equipment data; and Applications that visualize, analyze and report health equipment data.

Through regular monitoring of machine conditions, mines can adopt a more proactive approach to maintenance and repair. Equipment health data is a key contributor to that approach. Data helps mines identify equipment problems long before failure.

Accessing the right data at the right time is critical to improving operational intelligence and machine predictive analysis. Cat® MineStar™ Health helps you meet that need by connecting you to your machines and delivering that important information. The MineStar Health portfolio set consists of Connectivity Enablers that collect, convert and transmit equipment data; and Applications that visualize, analyze and report health equipment data.

Effective mining starts with accurate drilling. That means drilling every hole precisely to plan, at the proper angle and the correct depth. Cat® MineStar™ Terrain for drilling provides precision guidance that helps operators complete patterns accurately and productively. It pays other dividends, as well, by improving safety, reducing costs and recording data about drilled stratification to aid in planning blasts and improving fragmentation. And it works with all brands of drills and communicates seamlessly with MineStar and other mine management systems.

Effective mining starts with accurate drilling. That means drilling every hole precisely to plan, at the proper angle and the correct depth. Cat® MineStar™ Terrain for drilling provides precision guidance that helps operators complete patterns accurately and productively. It pays other dividends, as well, by improving safety, reducing costs and recording data about drilled stratification to aid in planning blasts and improving fragmentation. And it works with all brands of drills and communicates seamlessly with MineStar and other mine management systems.

Caterpillar product brochures and other informational documents are available for your growing business.

MD6310 Rotary Blasthole Drill

MD6310 Rotary Blasthole Drill

MD6310 Rotary Blasthole Drill

MD6310 Rotary Blasthole Drill

MD6310 Rotary Blasthole Drill

MD6310 Walkaround

MD6310 Launch Video

Thiess Review of Terrain for Drilling on MD6310

Thiess Review of MD6310 Drill

Cat Rotary Drill Rigs —— Next Level