Ratings

| Power Range | 400 - 500 bhp (298 - 373 bkW) 400 - 500 bhp (298 - 373 bkW) |

Key Specs

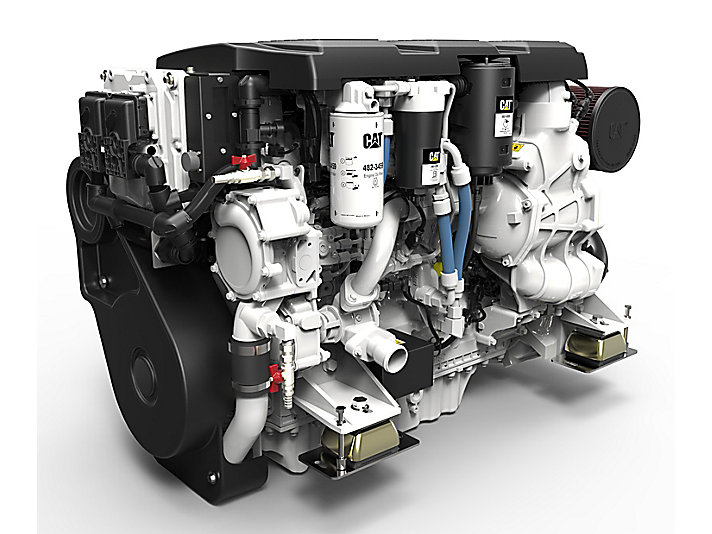

The C7.1 marine propulsion engine is ideal for recreational boating applications, specifically smaller vessels and motoryachts ranging from 25 -60 feet in size. The engine features a common rail fuel system enabling optimum combustion and low emissions. The engines provide noticeably quiet operation due to reduced combustion noise through advanced electronic control. Additionally, no visible smoke is emitted from the C7.1 engines during operation.

| Power Range | 400 - 500 bhp (298 - 373 bkW) 400 - 500 bhp (298 - 373 bkW) |

| Speed Range | 2900 rpm 2900 rpm |

| Emissions | IMO II, U.S. EPA Tier 3, RCD II, China II IMO II, U.S. EPA Tier 3, RCD II, China II |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Bore | 4.13 in 105 mm |

| Stroke | 5.31 in 135 mm |

| Aspiration | Turbocharged - Aftercooled Turbocharged - Aftercooled |

| Displacement | 428 in³ 7.01 l |

| Configuration | In-line 6, 4-Stroke-Cycle Diesel In-line 6, 4-Stroke-Cycle Diesel |

| Width - Engine | 31.4 in 798 mm |

| Height | 34.5 in 876 mm |

| Engine Dry Weight - Approximate | 1676 lb 760 kg |

| Length - Engine | 43.1 in 1095 mm |

Caterpillar product brochures and other informational documents are available for your growing business.

Use the comparison tool to compare detailed specs of Cat and competitor models.

Compare All ModelsC7.1 High Performance Propulsion Engine

Meet the new C7.1 Commercial Propulsion Engine

C7.1 Marine Propulsion Engine Walkaround