Weights

| Standard Weight | 6724 lb 3050 kg |

Key Specs

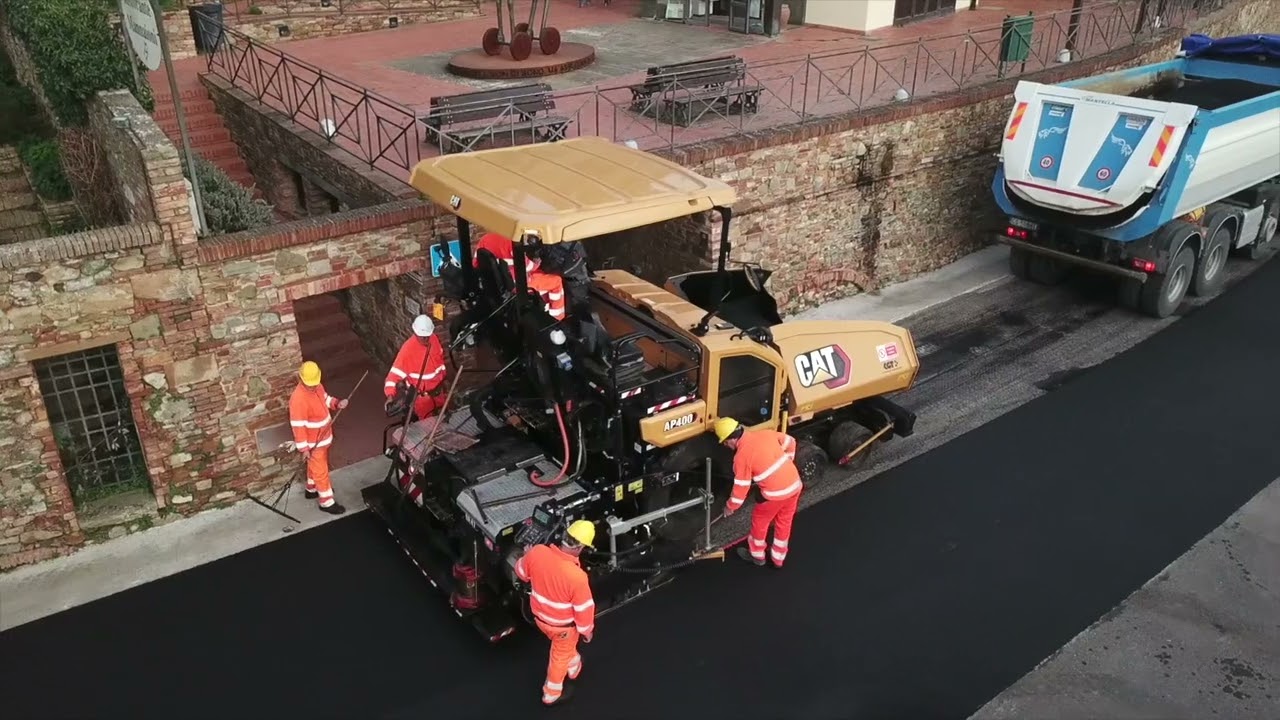

The Cat® SE47 VT Tamper Bar Screed is equipped with rear-mounted extenders that provide stability, easy set-up, and a versatile paving range, making it the perfect fit for both urban streets and rural paving applications.

Proportional control extenders, optional hydraulic end gates, and tamper bars equipped with automatic speed control are designed to enhance screed performance for good mat quality.

Intuitive controls and good visibility to adjustment gauges and material flow simplify operation.

The single amplitude, variable frequency tamper system combines with dual-carriage extenders to provide performance and stability.

| Standard Weight | 6724 lb 3050 kg |

| Standard Paving Range | 2.4 - 4.68 m (7' 10" - 15' 4") 2.4 - 4.68 m (7' 10" - 15' 4") |

| Maximum Paving Range | 19.6 ft 6 m |

| Tamper Speed Range | 500 to 1800 rpm 500 to 1800 rpm |

| Vibrator Speed Range | 0 to 3000 rpm 0 to 3000 rpm |

| Maximum Paving Depth | 12 in 300 m |

| Crown Range | -2% to +5% per side -2% to +5% per side |

| Extender Height Range | -5 mm to +15 mm -5 mm to +15 mm |

| Screed Plates Thickness | 0.5 in 12.2 mm |

| Screed Plate Width - Front to Back | 12.75 in 324 mm |

| Length - Front to Back, Endgates Attached | 82 in 2091 mm |

| Length - Front to Back, Endgates Removed | 62 in 1583 mm |

Caterpillar product brochures and other informational documents are available for your growing business.

SE47 VT Screed

SE47 VT Screed

SE47 VT Screed

SE47 VT Screed

SE47 VT Screed

AP400_SE47 VT

Leverage Caterpillar connected data and security principles to improve efficiencies, increase productivity and make your business more profitable.

Cat® Inspect allows you to access your equipment data on your mobile device. This easy-to-use app lets you capture inspection data and integrates with your other Cat data systems, so you can keep a close eye on your fleet. More than one million inspections are completed each year, providing convenience and accountability to equipment owners.

Remote Flash sends an alert from your Cat dealer, prompting you to update the software on your machine. To minimize downtime, updates can be deployed while on the jobsite without having to wait for a dealer technician to arrive. Remote flash decreases maintenance time and keeps your asset running with maximum efficiency.

Remote Troubleshoot allows your Cat dealer to run testing while the machine is operating. Once the problem is identified, a technician can fix it with the correct parts and tools the first time, saving time and money. Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency.

VisionLink™ is a cloud-based software application that takes the guesswork out of fleet management with key insights to maximize performance - regardless of fleet size or equipment manufacturer. Receive equipment data seamlessly to your desktop or mobile device, all from a convenient centralized solution to make informed decisions at every turn.

Cat® Inspect allows you to access your equipment data on your mobile device. This easy-to-use app lets you capture inspection data and integrates with your other Cat data systems, so you can keep a close eye on your fleet. More than one million inspections are completed each year, providing convenience and accountability to equipment owners.

Remote Flash sends an alert from your Cat dealer, prompting you to update the software on your machine. To minimize downtime, updates can be deployed while on the jobsite without having to wait for a dealer technician to arrive. Remote flash decreases maintenance time and keeps your asset running with maximum efficiency.

Remote Troubleshoot allows your Cat dealer to run testing while the machine is operating. Once the problem is identified, a technician can fix it with the correct parts and tools the first time, saving time and money. Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency.

VisionLink™ is a cloud-based software application that takes the guesswork out of fleet management with key insights to maximize performance - regardless of fleet size or equipment manufacturer. Receive equipment data seamlessly to your desktop or mobile device, all from a convenient centralized solution to make informed decisions at every turn.

The Cat® Grade and Slope system is designed to remove irregularities from the paved surface. The system consists of sensors to control elevation and slope. These sensors can work individually or together to make automatic elevation or cross slope adjustments and maintain the targeted values. Averaging beams equipped with multiple sensors provide a longer averaging area to help remove irregularites for smoother transitions.

The Cat® Grade and Slope system is designed to remove irregularities from the paved surface. The system consists of sensors to control elevation and slope. These sensors can work individually or together to make automatic elevation or cross slope adjustments and maintain the targeted values. Averaging beams equipped with multiple sensors provide a longer averaging area to help remove irregularites for smoother transitions.