Powering Caterpillar’s Future with Alternative Fuels

It’s Not About The Best Fuel. It’s About The Best Fuel For The Job.

What’s the stat everyone looks at when choosing an engine? Horsepower. The word itself is a reminder of how far our power sources have come — from horses to steam to diesel and beyond. What’s next? For Caterpillar, the answer is fuel flexibility. Rather than a single solution, we’re focused on multiple options to meet our customers’ evolving needs.

Fuel Flexibility from Day One

Steam engines grabbed the power reins from horses in the 1800s, thanks to their ability to provide more power at a lower cost on farms, in factories and for transportation. But steam had downsides, too: Engines were heavy and difficult to move. Additionally, they presented safety challenges and emitted hot cinders that could ignite a farmer’s fields.

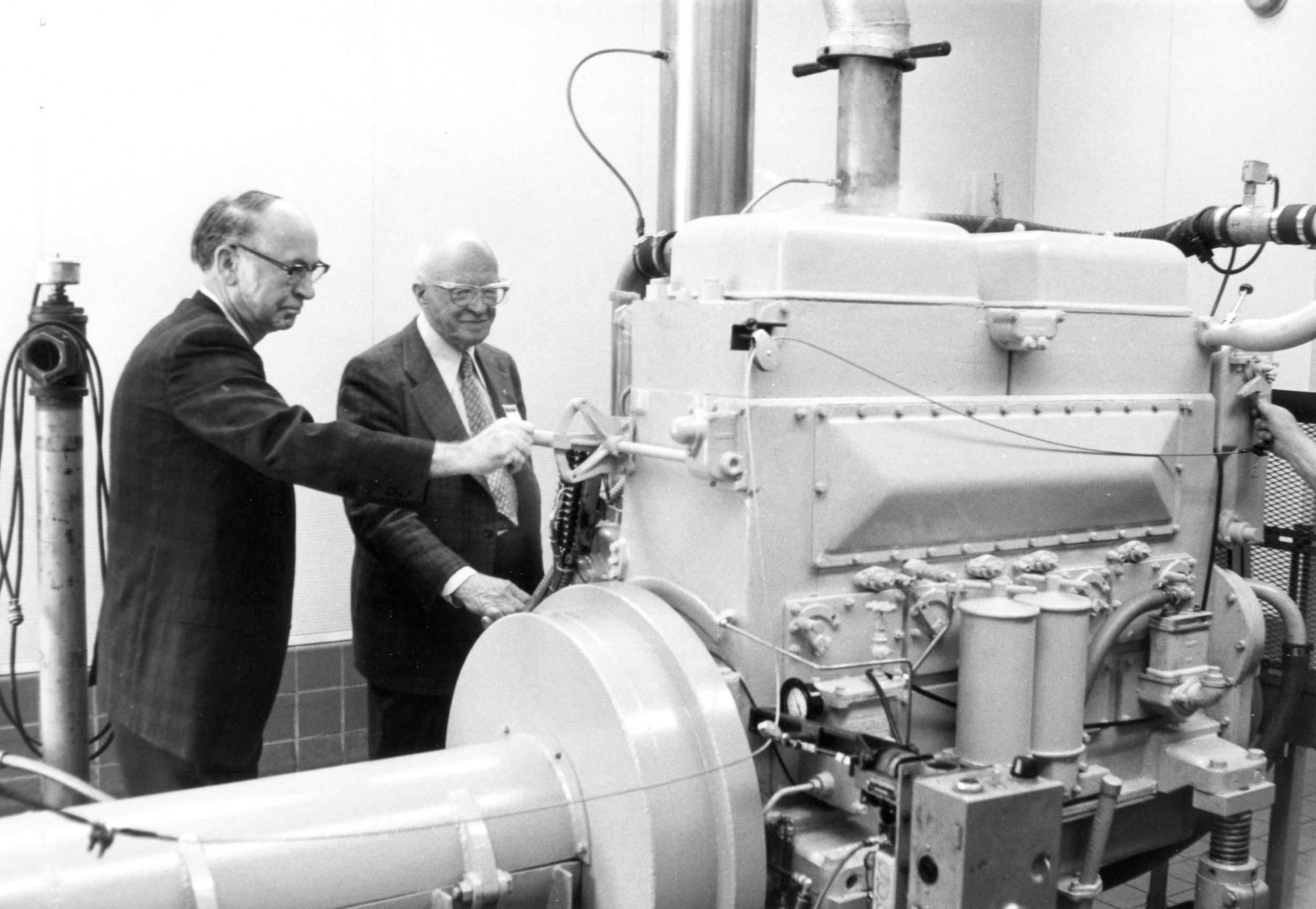

Recognizing the limitations of steam power, Caterpillar co-founder Benjamin Holt began experimenting with tractors powered by gasoline as early as 1906. We built our first diesel-powered engine, nicknamed “Old Betsy,” in 1930. Later that same decade, we converted our dozers to run on butane and propane.

In the years since, we’ve continued to re-engineer our engines to run on a wide spectrum of fuels — from liquified natural gas to methanol and biofuels like hydrotreated vegetable oil (HVO). Long before the world was talking about an “energy transition,” we recognized the opportunity to use different fuels in different applications to enhance our customers’ performance and efficiency.

Alternative Fuel Innovation: A Variety of Options

So what’s the next big thing in fuels? Though it’s trendy to point to options like hydrogen or methanol as the perfect fuels for energy transition, we don’t believe in a one-size-fits-all solution.

Consider this: There are more than four million Cat® products currently at work around the world. The differences in how our customers use these products — geography, application, scale and more — are tremendous. And these differences are what drive our exploration into potential fuel sources.

What works in a stationary genset may not work in a moving machine. What holds up in the Arctic may break down at the equator. Different engines may react differently to traditional liquid fuels versus biofuels versus gases. Plus, fuel sources that seem impractical today may be more feasible tomorrow as science and infrastructure advance.

For all these reasons, we’re focused not on a single fuel solution but on fuel flexibility. We design our engines to adapt to multiple fuel types and concentrations of fuel blends. That way, we can give our customers options to do the work while contributing to their sustainability goals.

Flexible Engine Design for Maximum Compatibility

Engines don’t exist in a vacuum. They’re part of a bigger system, and if the quality of one component falters, it can affect the performance of the whole.

That’s why we include fuel use and compatibility as part of our engine design process. World-class materials and heat-treating processes help us ensure the viability of our engines when used with various fuel types and blends — and allow us to avoid any sacrifices to quality or durability.

Our engineers use this time to troubleshoot any challenges raised by various fuel types, identify root causes and modify designs accordingly. Including fuels in the development process also helps us accelerate innovation, so we can bring more options to the table faster.

Customer feedback is key, too. We work with customers to test various engine and fuel types in the field, across a variety of different applications and environments. With their input, we can make adjustments that make the use of certain fuels more practical.

Alternative Fuel Solutions: Will They Actually Work?

“Will it work?” is just the first question we need to answer about fuels, though. We also have to ask, “Is it readily available?” “Is it safe?” and “How much does it cost?” After all, what good is an engine if you can’t access or afford the fuel required to run it — or if using that fuel could put people and property at risk?

Take hydrogen, for example. When created using renewable energy, it’s a zero-carbon fuel that could be instrumental to a reduced-carbon economy. Hydrogen also offers advantages in applications where carbon emission reductions are difficult such as long-term energy storage, chemical and industrial processes and heavy-duty transportation. Today we offer a Cat G3516 gas generator that can operate on 100% hydrogen.

But that doesn’t mean everyone can just switch to hydrogen. It contains less energy per volume than options like natural gas, and pipeline infrastructure is currently limited, so users may need to store large volumes on site and manage the associated risk. These limitations make it a less-than-desirable option for some customers.

Hydrogen and natural gas blends — like this advanced hydrogen-hybrid power solution built on our new C13D engine platform — often are more feasible alternatives. Another potential solution is a hydrogen fuel cell system, which can provide electricity for applications from utility power stations to EVs. We’ve been collaborating with Microsoft and Ballard Power Systems to demonstrate the viability of large-format hydrogen fuel cells to supply reliable, sustainable backup power for data centers.

Tailored Fuel Solutions for Cat Customer Needs

Since Caterpillar’s earliest days, we’ve seen power sources evolve from horses to steam to diesel to all manner of alternative fuel types. There’s never been a single option that served every customer, and we doubt there ever will be.

That’s why we remain focused on developing tailored, flexible solutions that help our customers adapt to changing times. Finding the best fuel for the job is a strategy that’s worked for a century — and one we’re confident will help our customers continue to tackle their toughest challenges while meeting their sustainability goals.

DID YOU KNOW? Cat engines have been engineered to run on a number of different fuels including diesel, methanol, methane, liquified natural gas, biogas, biodiesel, biomass-to-liquid (BTL), gas-to-liquid(GTL), HVO and hydrogen.[1] Learn more about our renewable fuel options here.

Related Stories

-

Sea Bubble Curtains

Discover how ScanTech Offshore uses Cat® engines to build sea bubble curtains that protect marine life during offshore wind farm construction.

Learn More -

FAQS: What Are Renewable Fuels?

Renewable diesel fuels… they're kind of like nature's gift to our engines. So, what is renewable diesel fuel, exactly? We're talking about fuel made from stuff like soy, palm, canola, even used cooking oil and animal fat.

Read more -

HVO Engines

Read about the Cat® C Series engines that can operate on Hydrotreated Vegetable Oil (HVO) fuel while reducing CO.

Read more -

Mulching to Reduce Greenhouse Gas Emissions

A method of sustainable waste management is turning landfill waste into mulch. With Cat® powered grinders, cities can reduce greenhouse gas emissions & landfill capacity.

Learn More