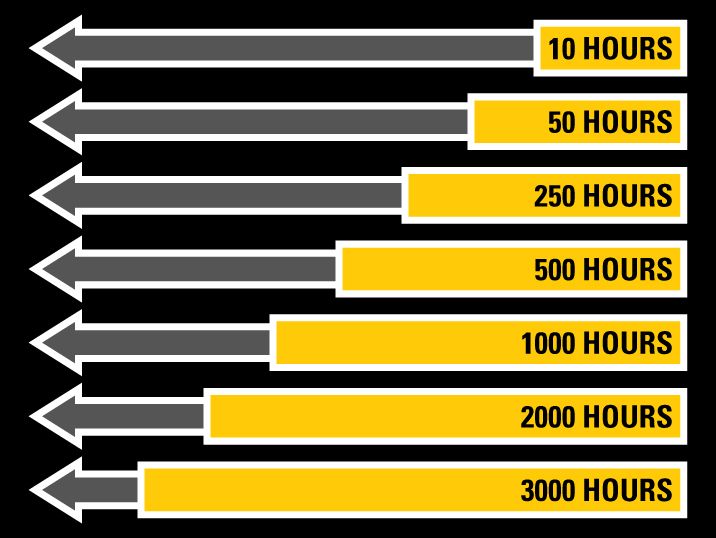

Small Dozer Maintenance

Learn small dozer maintenance, simple diagnostics and more.

Maintenance Videos

Parts and Attachments

Whether you’re looking for Cat® greases, ground engaging tools, wear parts, replacement parts or planned maintenance kits — we’ve put it all in one place. Browse our guide book for part options and corresponding part numbers.