HYDROGEN AS A FUEL FOR RECIP ENGINES

TECHNICAL CONSIDERATIONS

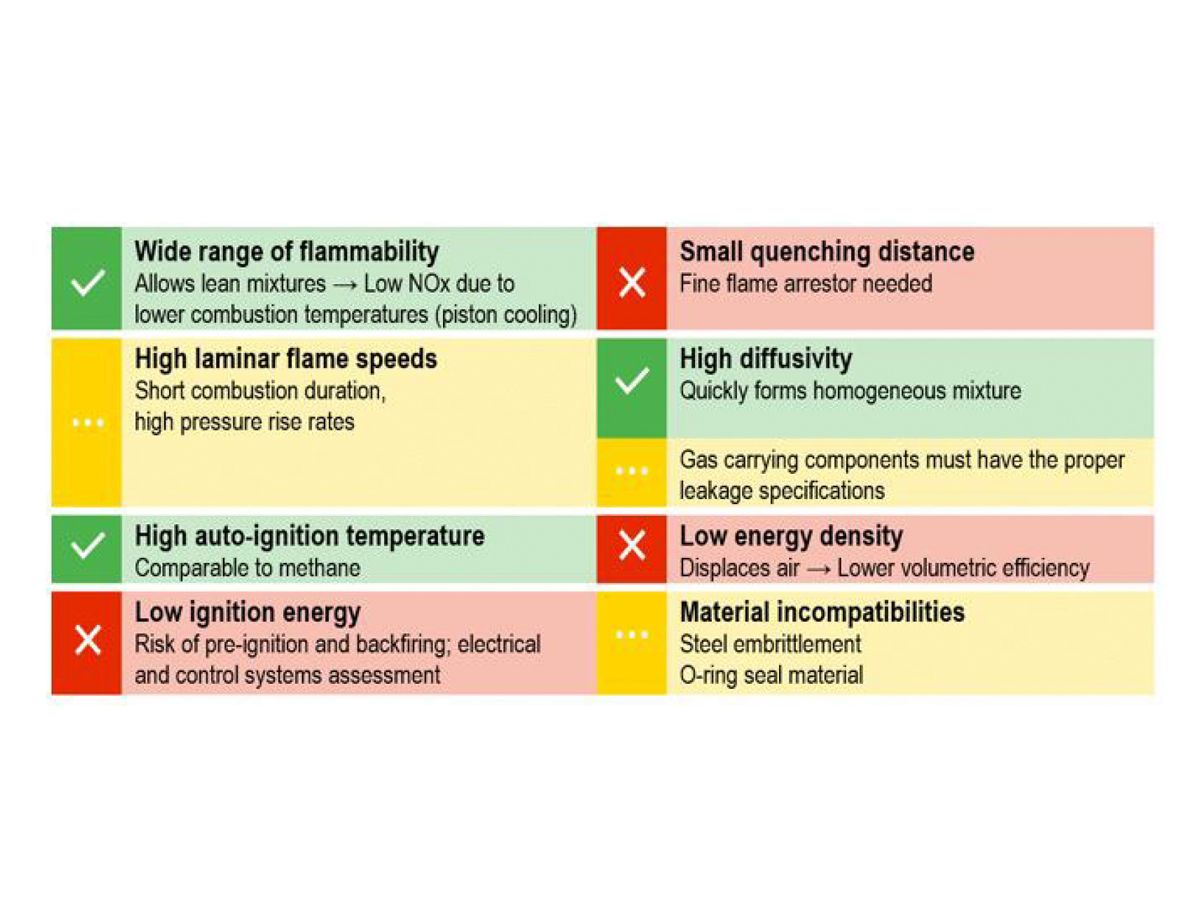

While the design of a hydrogen-enabled recip engine is similar to a standard natural gas engine, there are several factors to consider when accounting for the distinct properties of hydrogen. As shown in Figure 4 below, Caterpillar distinguishes these factors as follows:

- Green: Positive factors.

- Yellow: Factors to be considered but which can be managed.

- Red: Factors requiring significant modifications or with a safety concern.

The first of the positive (green) considerations for hydrogen is its wide range of flammability. This allows very lean fuel mixtures that combine with very low combustion temperatures to result in low NOx values. However, such low combustion temperatures may require a change in the engine’s cooling system.

The high diffusivity from hydrogen helps to form homogeneous mixtures and to create a well-mixed charge in-cylinder when utilizing port injection or direct injection fuel systems.

In considering manageable (yellow) factors, high laminar flame speed is positive because there is better efficiency out of the short combustion duration, but high pressure rise rates add mechanical stress to the engine. This increased mechanical stress can be managed through a combination of engine design and power derate. High auto ignition temperatures comparable to methane require no related changes.

Consideration must be given to the specifications for gas-carrying components to minimize the incidence of hydrogen leakage. To that end, one should adhere to suppliers’ application and installation instructions for items like proper engine room ventilation and proper hydrogen gas train installation.

Also, consideration must be given to material incompatibilities, specifically the steel embrittlement and O-ring deterioration caused by hydrogen. This requires careful analysis to ensure the correct materials are used in the engine.

Regarding the factors requiring significant modifications and/or safety concerns (red), low ignition energy increases the risk of knocking, pre-ignition, and backfiring, which drives the need for good engine control systems and management of the electrical systems per safety regulation requirements.

Small quenching distances drive the need for flame arrestors to have a much smaller mesh size in order to prevent combustion of the charge in the intake manifold which itself is a safety concern. The smaller mesh size requires higher air intake pressure, unless the size of the arrestors is increased. An alternative to fine mesh flame arrestors, used for hydrogen mixtures above 25%, to prevent pre-ignition in the intake manifold is port or direct injection of hydrogen.

Finally, the low density of hydrogen means there is less energy on a volume basis. A turbocharging system with a higher charge air pressure could be required to compensate for this factor and minimize the volumetric efficiency impact.

USER IMPACTS

The factors prioritized by many users of hydrogen include fuel source, power output, efficiency, emissions, capital and operating costs, and safety.

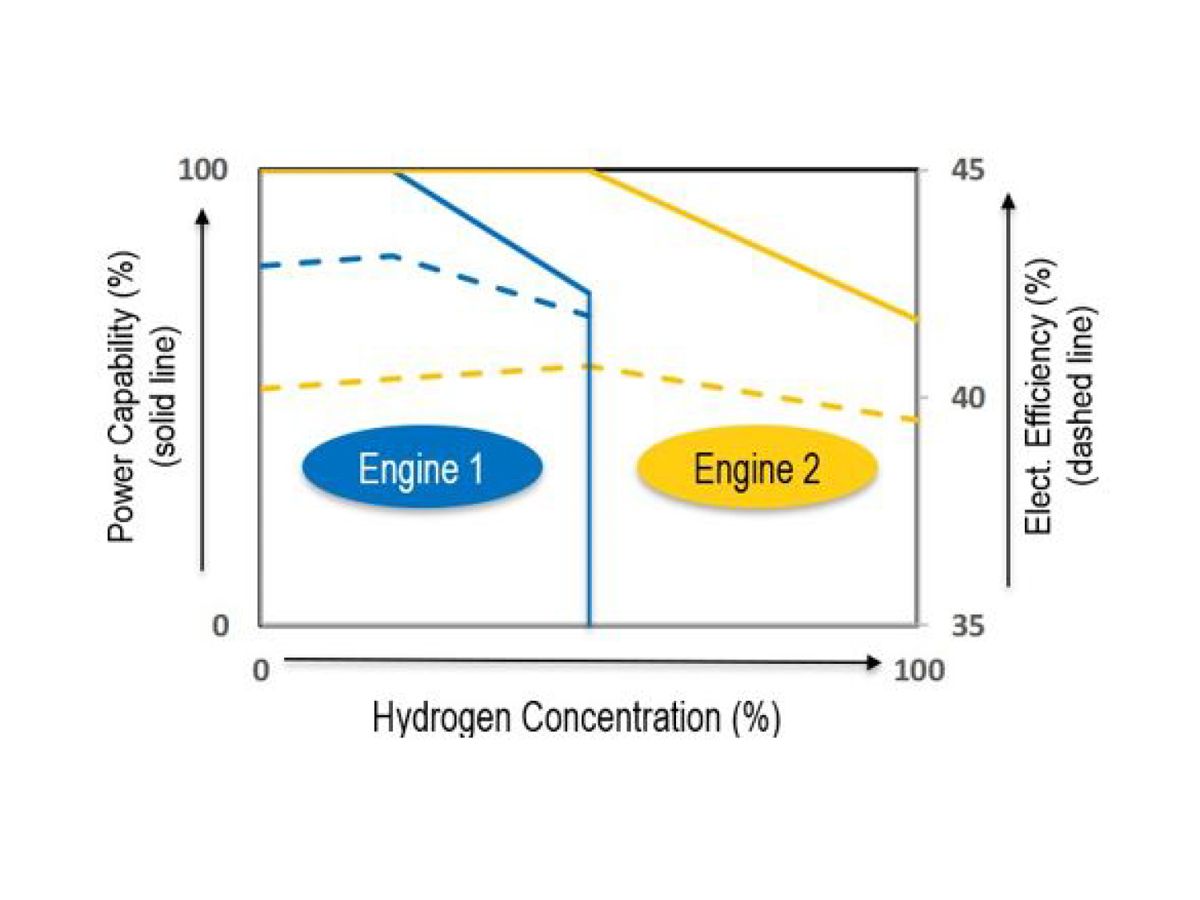

Different engine configurations can be optimized for power, efficiency, or hydrogen blending, but there are tradeoffs. This is illustrated by the performance of two hypothetical engines, as shown in Figure 5.

The blue oval represents a typical natural gas engine available on the market. This engine is able to operate with a hydrogen blend of up to approximately 25% without any significant derate. Thereafter, the engine derates until it can no longer run due to detonation, at which point the engine cannot accept additional load. However, efficiency is not affected, and in fact, it slightly increases when raising the hydrogen concentration from 0% to slightly under 25%.

The yellow oval represents an engine similar to those available on the market but with a decreased compression ratio, as well as minor changes to the software and the turbocharging system. This engine is able to operate with a hydrogen blend of up to 60% without any significant derate, and thereafter with a derate up to 100% hydrogen, where it is rated at approximately 60% of the natural gas rating. The electrical efficiency is lower than that of the production engine due to the lower compression ratio, but it stays more or less stable at 40%.

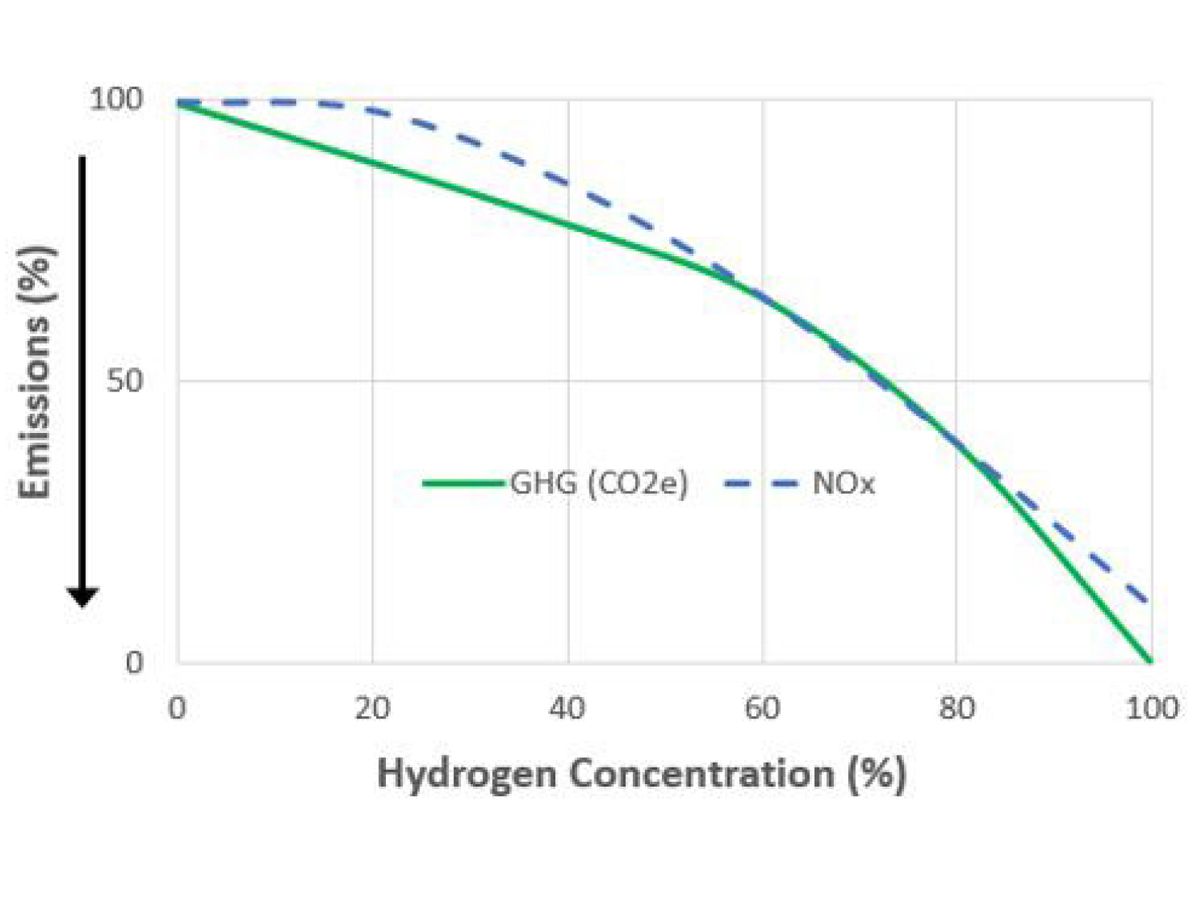

The GHG emissions of hydrogen steadily decrease to zero as the mixture goes to 100% hydrogen, as shown by the green line in Figure 6.The GHG and NOx reductionwith hydrogen blends isdetermined by the enginecombustion and controlssystems.

The blue dotted line shows an example of one engine configurations with a varying levels of blended hydrogen. For this engine, NOx emissions are unchanged up to about 20% hydrogen but thereafter the NOx emissions decrease. At 100% hydrogen, NOx emissions are approximately 10% of the initial value and there are virtually no GHG emissions. Also, there are no unburned hydrocarbons, which means an oxidation catalyst is not needed.

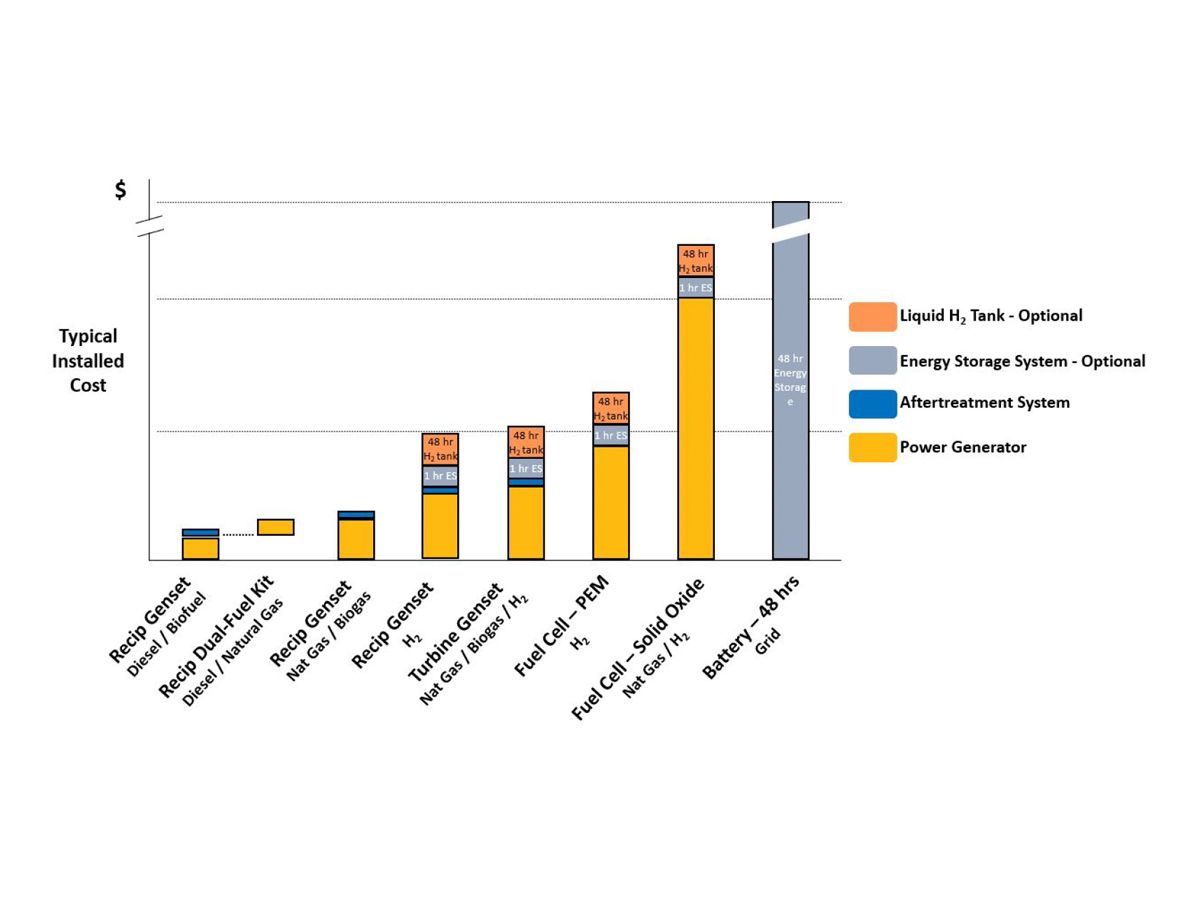

This results in a win- win situation, with very low initial cost and clean exhaust gas. The concept of low emissions and capital costs has been demonstrated in data center applications with 3 MW generator sets, which is a typical rating node for this application. User installed costs for different technologies are shown in Figure 7.

The initial costs of diesel engines are relatively small, and they increase when looking at natural gas engines because of the lower power density. Initial costs increase again with hydrogen engines. In all cases, the cost of a generator set is still not high when compared with current fuel cells and batteries. Though the costs for fuel cells and/or batteries may fall in the future.

Additional costs are shown in blue for aftertreatment systems, while energy storage systems are shown in gray. Energy storage is a technology which can be utilized in conjunction with recip engines, turbines, and fuel cells to achieve transient performance requirements, but it does add costs.

Finally, the salmon bars represent a relatively larger portion of the infrastructure cost for liquefied hydrogen tanks, which can raise the initial cost of a recip engine generator set using hydrogen to approximately three times that of a recip generator set using diesel fuel.

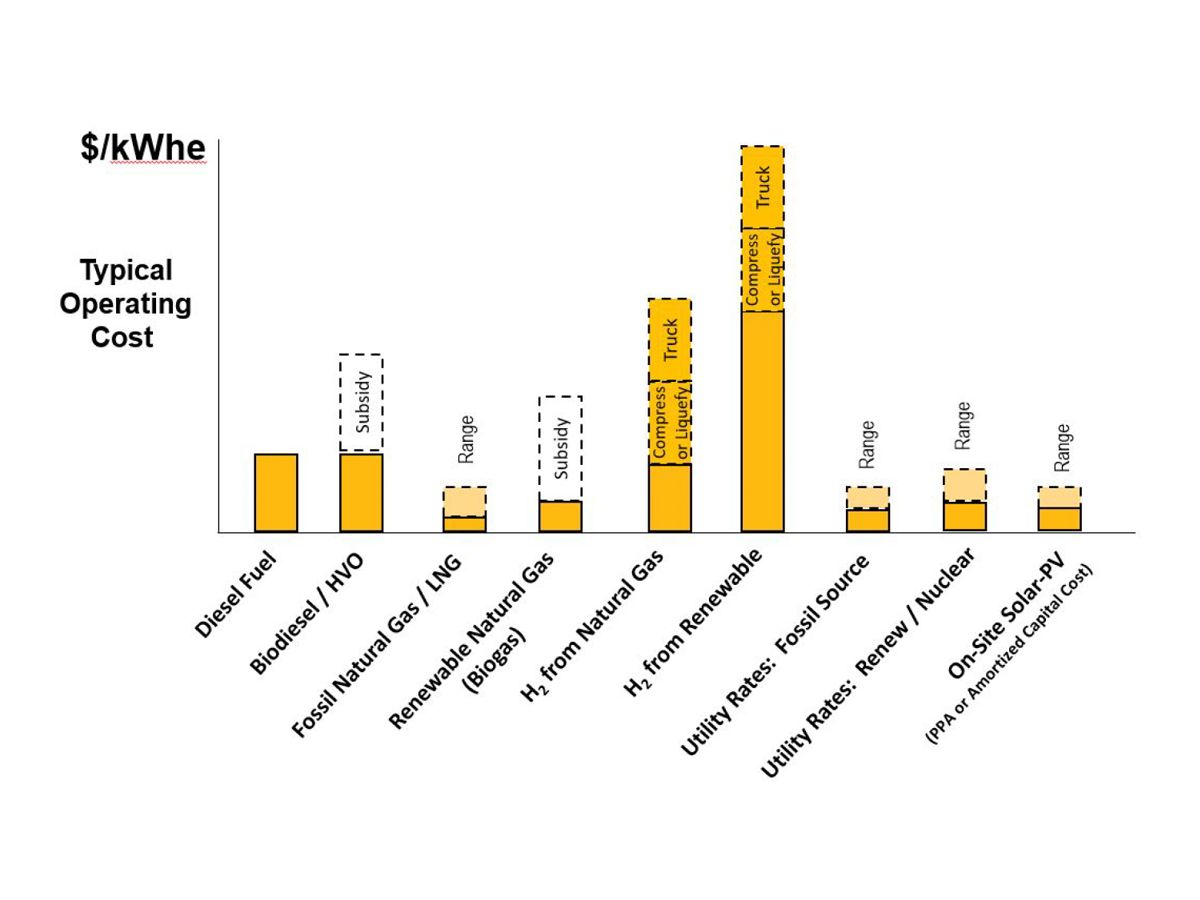

A different picture emerges when considering operating costs, as shown in Figure 8. Operation with natural gas is less costly than diesel since it is a less expensive fuel. When considering hydrogen produced from natural gas (gray hydrogen), the costs for the fuel itself are still below that of diesel. However, two additional bars represent costs to liquify or compress hydrogen and then transport it.

When considering hydrogen produced from renewables (green hydrogen), the additional costs for infrastructure are the same, but the production costs are expected to be five times higher than those for gray hydrogen through the 2025 timeframe. This highlights the need for supportive policy framework and investments in green hydrogen infrastructure to reduce production costs and make green hydrogen commercially viable.

The production costs of renewable hydrogen are eventually expected to be reduced and could match natural gas or diesel.

With respect to safety, hydrogen is odorless, tasteless, and colorless, and current odorants are not light enough to travel with hydrogen. As a result, readily available sensors are needed at all times to detect hydrogen concentrations.

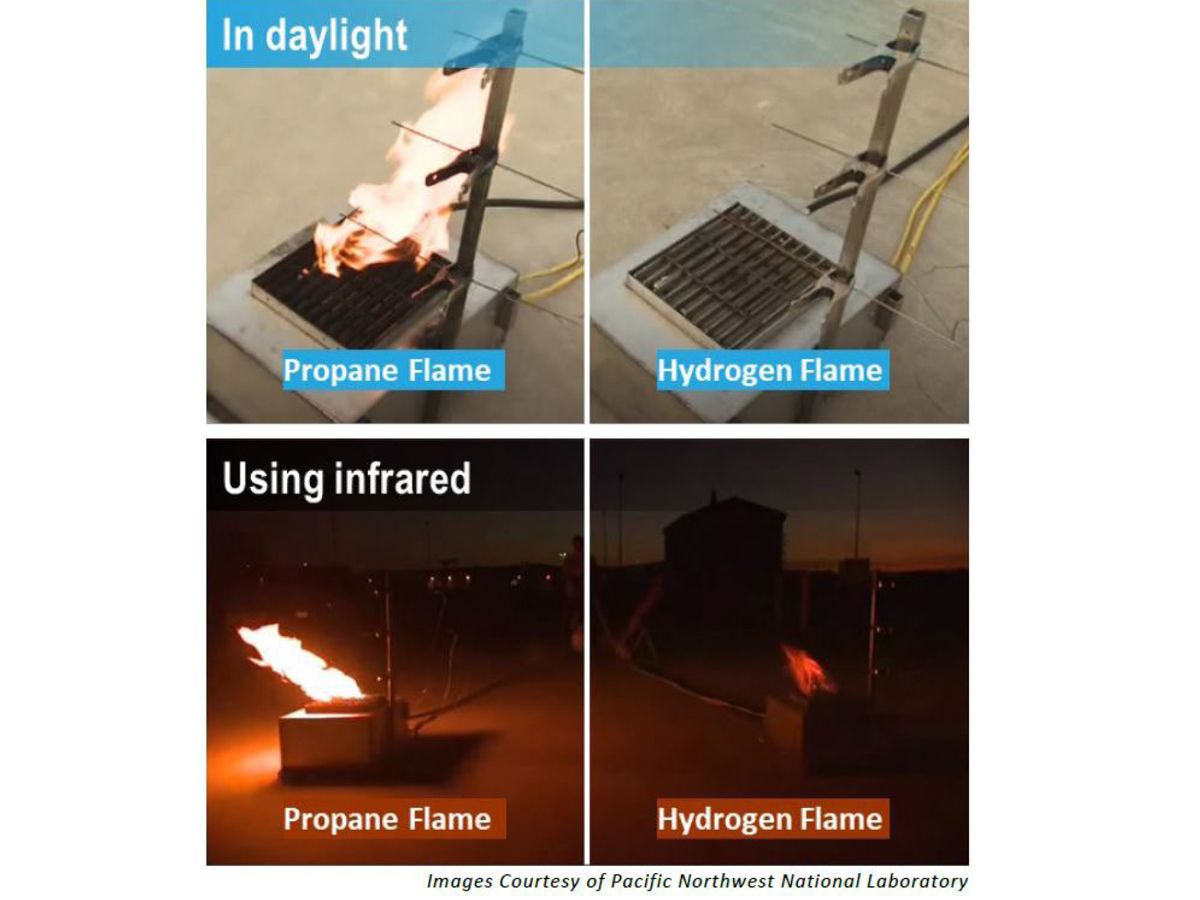

Figure 9 shows photos of propane flames next to hydrogen flames and prove the difficulty in visually detecting hydrogen flames. The propane flame is highly visible in daylight, while the hydrogen flame is nearly invisible. Using an infrared filter, the propane flame is highly visible, while the hydrogen flame is barely visible.

CATERPILLAR’S OFFERING FOR HYDROGEN

Caterpillar has experience using a wide range of alternative fuels in its gas generator sets. This includes hundreds of thousands of operating hours using hydrogen fuel mixtures.

Caterpillar views green hydrogen as one of the fuel sources that can contribute to a reduced-carbon future. It is currently testing or has plans to test higher hydrogen mixtures and 100% hydrogen on single-cylinder engines at Caterpillar facilities and multi-cylinder engines at Caterpillar facilities and customer sites. This work leverages Caterpillar’s deep performance simulation experience, especially on combustion and flame propagation.

In addition, work is underway on projects funded by grants from the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) and the German Federal Ministry for Economic Affairs and Energy (BMWi). The EERE project involves a 2.0 MW combined heat and power (CHP) system and will demonstrate flex-fuel operation on 100% hydrogen as well as various blends of hydrogen and natural gas. The BMWi project will involve a 400 ekW generator set running on various mixtures of up to 100% hydrogen to better understand load and efficiency optimization.

The experience and development work referenced above will allow the commercial launch of solutions for Cat gas gensets rated 400 – 4,500 ekW to operate on up to 25% hydrogen blends by the end of 2021. This will be concurrent with the commercial launch of the G3516H generator set at a rating of 1,250 ekW configured for 100% hydrogen.

CONCLUSION

Hydrogen, specifically green hydrogen, is one of the fuels being considered to help to reduce the carbon footprint of those involved in on-site power generation using recip engines.

There are a number of factors influencing mass adoption of hydrogen as a fuel source. Some of these factors should see positive movement in the coming years.

While there are a number of tradeoffs and factors to consider in burning hydrogen in recip engines, hydrogen can add value for on-site power generation applications.

Caterpillar is already offering recip engines (and turbines) capable of operating on hydrogen and hydrogen blends. We continue to improve the capability of hydrogen-powered reciprocating engines with minimal impact on maintenance costs and schedules, availability, and operations. We are continuing to invest in hydrogen technology and are well positioned to serve the needs of power generation customers and the marketplace as green hydrogen becomes more readily available.