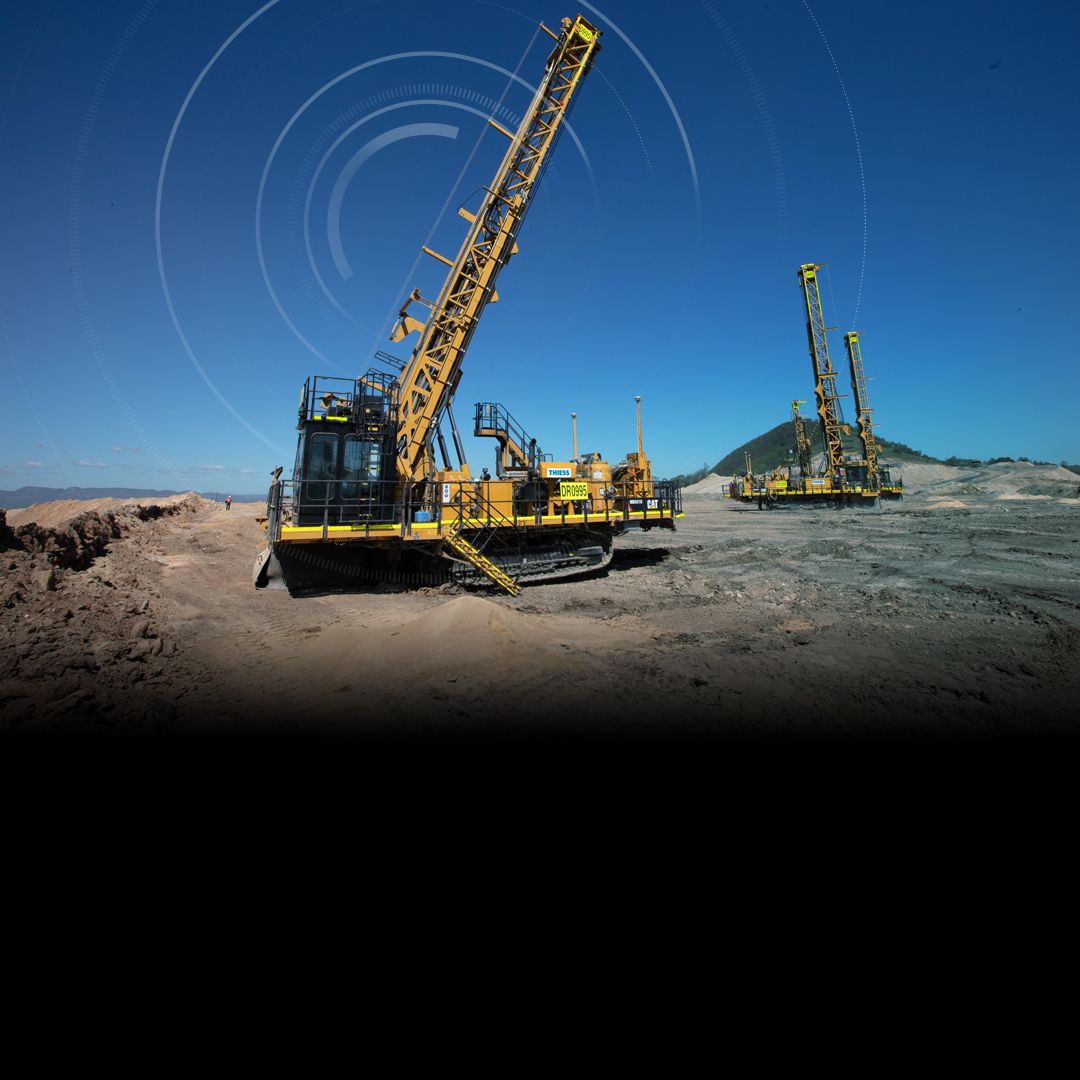

Cat® MineStar™ Solutions for Integrated Surface Operations

MineStar is the mining industry’s most comprehensive and thoroughly integrated suite of technology offerings. Fleet management, guidance technologies and machine health applications allow significant improvements in your operations and maintenance organizations. Safety technologies help keep people safe when they’re in, on or around equipment. And you can further optimize your operation with MineStar automation technologies, including fully autonomous hauling — a safety and productivity game-changer.

Choose Your Application

Are you looking for a solution that will address a specific aspect of your mining operation? MineStar Solutions can help. They work with all types of assets and integrate with any brand of equipment, sharing data across existing machines, systems and technologies.

Surface Technology Offerings

What's Your Challenge?

Solutions