If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

CAT® JOB SITE SOLUTIONS

What if you could reduce your operating costs by 10%, or sustain mechanical availability above 90%? What if you could build a safety culture demonstrated across your entire organization? Or improve your operational performance and put more to your bottom line? Our team of experts can make it happen.

It doesn’t matter if your job site is a mine, quarry, waste handling operation or construction site; we provide tailored, scalable solutions to help you succeed. Caterpillar and your local Cat dealer provide a strategy, intended outcomes, and a plan for action that meets the unique challenges of your business – and we help you execute it. We’re ready to work alongside you to solve problems and be a partner in your performance, helping you optimize your equipment, your people and your overall operation.

We focus on your success, leveraging our respective capabilities to get the business results you’re targeting.

WANT TO LEARN MORE?

WHAT CAN WE ACHIEVE TOGETHER?

PRODUCTIVITY

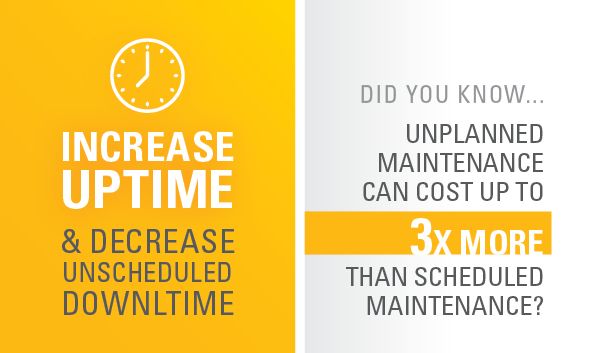

MAXIMUM EQUIPMENT VALUE

SAFETY

SUSTAINABILITY

OPTIMIZED FINANCIALS

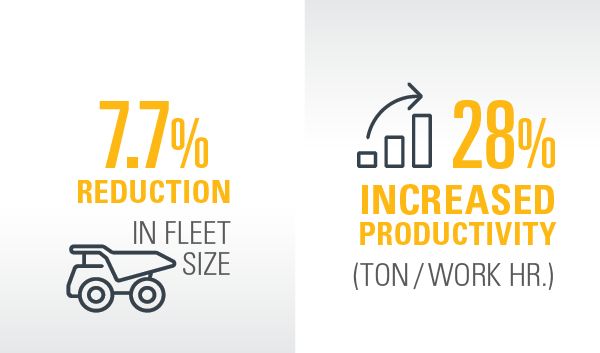

What does it mean to improve productivity? There are a number of tactics based on metrics you determine, such as:

- Increasing production

- Making operators more efficient/enhance skills

- Improving site design

Each of these can lead to significant, measurable gains — like these real results from customer sites.

FOCUSED ON OUTCOMES

Check out just a few examples of the many ways in which Cat Job Site Solutions can help improve your operation — or even multiple operations — in the videos below.

REAL NUMBERS, REAL CUSTOMER EXPERIENCES