If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Caterpillar and Reagan Power: An Electric Partnership

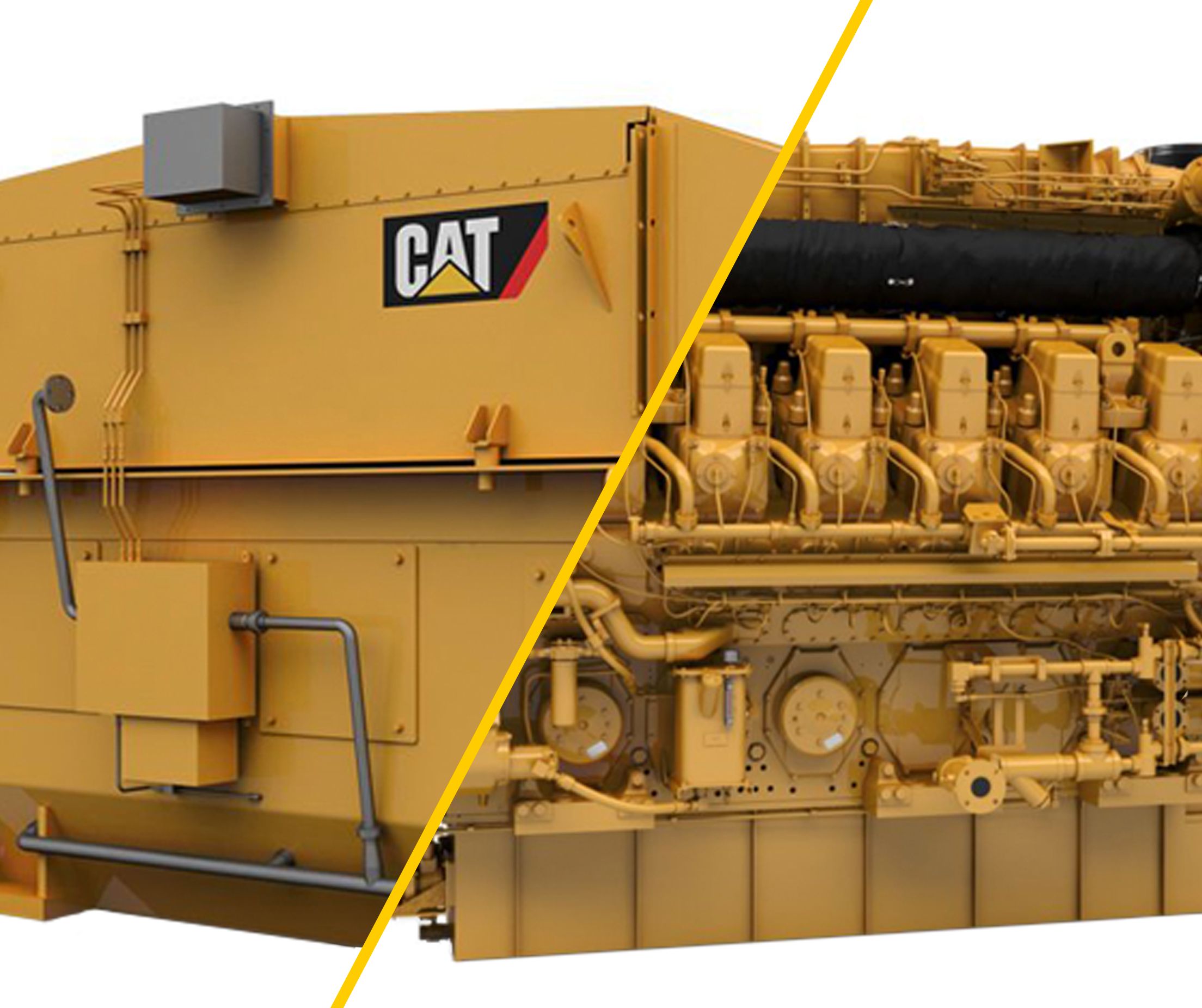

Caterpillar has long had a powerful presence in the gas compression industry, but with the help of Reagan Power and Compression, its electric motors are strengthening that presence further. Caterpillar recently delivered four of its CN2586 electric motors, each capable of delivering 2,250 horsepower, to Reagan for packaging. It’s an exciting partnership that Edward Porras, a member of Caterpillar’s corporate accounts team, and Jason Sowels, Reagan’s director of business development introduce here, along with Caterpillar’s electric motors.

Caterpillar’s electric motors are backed by its globally-respected dealer network and join a family of power systems that are already proven, says Edward Porras.

“Many people around the world in the gas compression industry recognize Caterpillar as a premier manufacturer of natural gas fueled engines. But now Caterpillar offers a line of electric motors designed specifically for the gas compression industry. We can handle applications from 1,000 horsepower to 10,000 horsepower. They’re available at your local dealer and can provide sales and service.”

The CN2586 is designed with a 900 to 1200 rpm range and sleeve bearings, making for easier and more predictable maintenance scheduling. Sleeve bearings also allow for quieter operation and are engineered to prevent sudden failures. And with Caterpillar’s focus on quality materials and construction, the bearing is protected from excessive heat and moisture. Of course, Caterpillar includes RTD sensors to measure all bearing temperatures and ensure they are operating within safe bounds.

Caterpillar has made durability a true focus of the CN2586, as its blower motor will activate at a lower speed, helping control winding temperature. The blower is supported by an air hood designed for maximum structural integrity, so it can handle the additional force produced by the blower with no trouble.

Most notable, though, is the high strength shaft that out-competes most competitors. The extra strength allows for more turndown, and that means greater application flexibility and better adaptability as work conditions change.

It’s the total package, according to Jason Sowels.

“This motor was designed for standard gas compression spec applications and it’s a perfect fit for reciprocating applications.”

RELATED ARTICLES

-

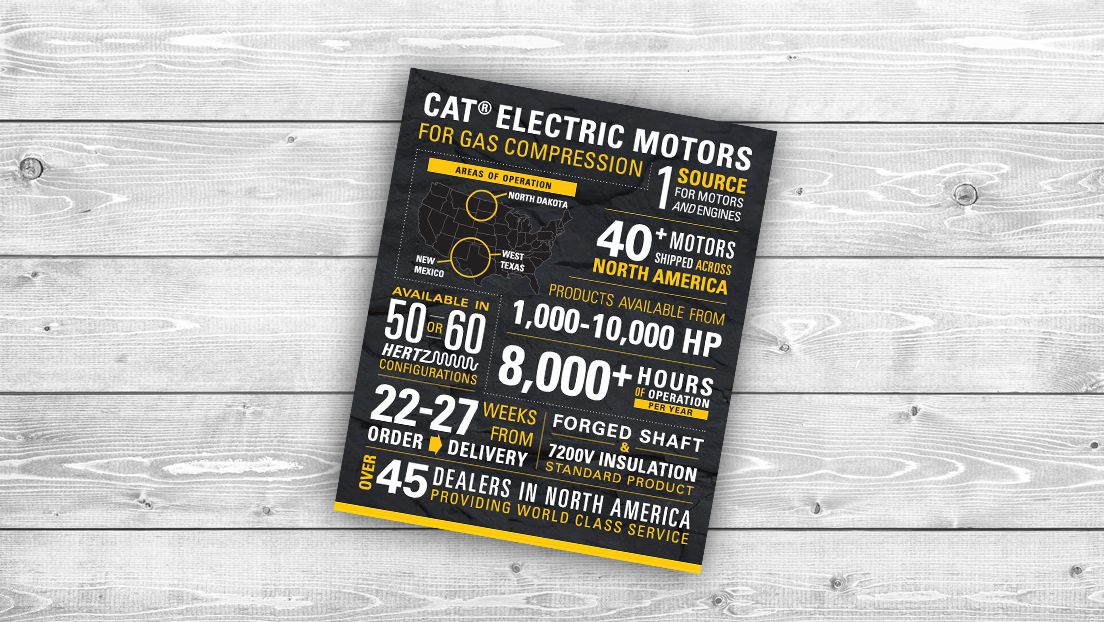

By the Numbers: Cat® Electric Motors for Gas Compression

Zero site emissions. Virtually no maintenance. Fast delivery. Take a by-the-numbers look at all the benefits of Cat electric motors for gas compression.

Learn More -

Crestwood Adds Electric Motors, Drives Down Costs & Emissions

With 60% of its in-the-field horsepower coming from Cat® gas reciprocating engines, Crestwood is no stranger to Cat power. But Cat electric motors are new — and delivering on all their promises.

Learn More -

Need an Electric Motor? Caterpillar Has You Covered

Need an Electric Motor? Caterpillar Has You Covered

Learn More