If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Stinger 6500 & 8500 Stackers

Read profile

Product Overview

Cat® Product Overview

Gallery

Related Profiles

POWER PROFILE

CUSTOMER:

LOCATION:

Burrton, KS

EQUIPMENT

Stinger 6500 & 8500 Stackers

PRODUCT:

Cat® C9.3B EU Stage V, U.S. EPA Tier 4 Final

DEALER

SECTOR

STACKING UP AGAINST THE COMPETITION

Stinger serves customers with farms ranging from a couple hundred acres to several thousand. It offers the single-axle Stinger Stacker 6500 and tandem-axle 8500 models of self-propelled bale handlers. In the hay business, speed and efficiency are critical—as is power—to outpace the weather and deliver quality crops.

Bales can weigh between 1,500 and 2,000 pounds each. The 6500 can stack up to six bales at a time. The 8500 is designed to haul and stack up to 14 bales per load. Moreover, both models can transport bales at up to 45 mph fully loaded, even in rough terrain, soft fields and adverse conditions.

RAMPING UP THE POWER FOR MORE PRODUCTION

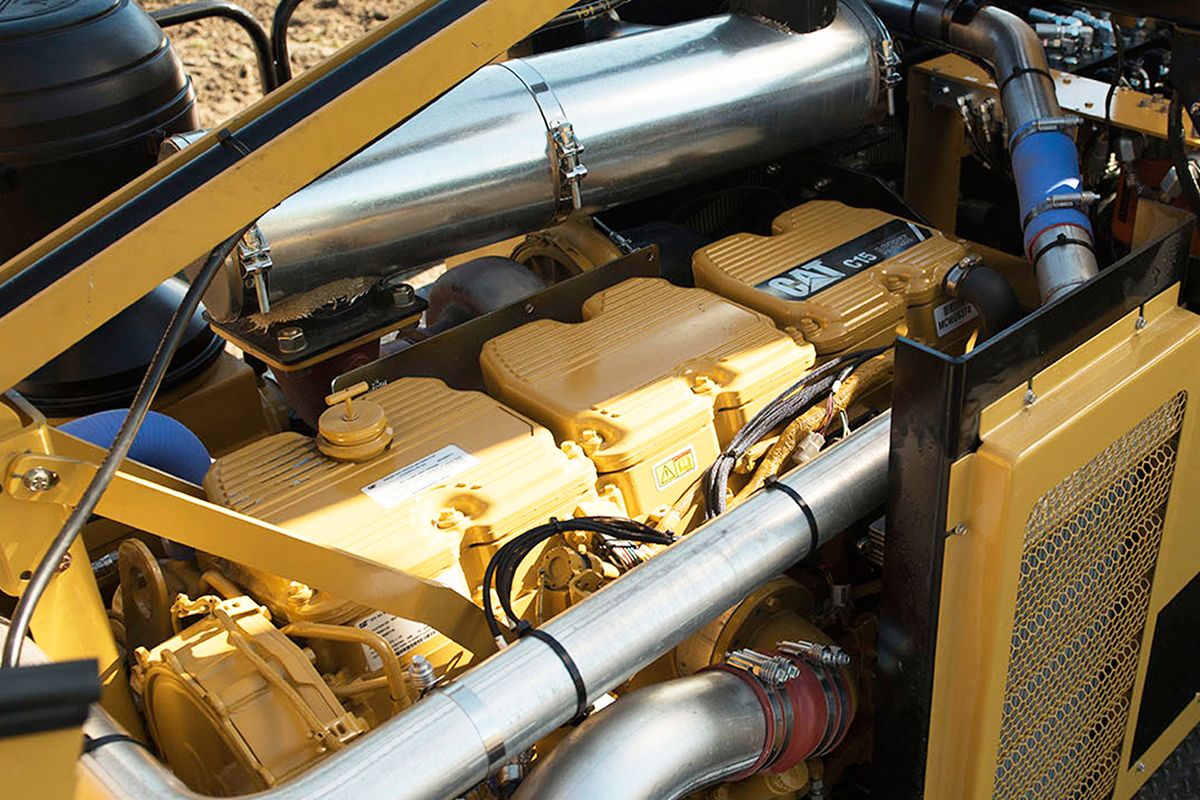

Striving for continual improvement, Stinger has redesigned and now manufactures its custom, heavy-duty, off-road chassis in house. It turns to Caterpillar for power. Between the high-tensile, steel-frame rails, the Cat® C9.3B engine is the power within the Stacker. It has more power and torque than previous models and is lighter and more compact. The Cat C9.3B can handle stop-and-go action for long hours. Variable travel speeds, heavy loads, rough terrain and hydraulic demands are tough on engines. Stackers are not like field tractors that can run at the same engine speed all day.

CHOOSING CATERPILLAR WAS EASY

When designing its chassis, Stinger wanted the best engine fit for its customers and explored more than a half dozen different manufacturers. Caterpillar’s willingness to work with a small manufacturer was the main reason Stinger chose to use Cat power. “Other engine manufacturers only wanted to work with companies that produced high volumes of equipment,” says Stinger President, Karl Matlack. “Caterpillar also offered a single engine that fit both models, saving customers in future parts and service needs.”

The Cat C9.3B also allows Stinger to give its machines more power density while avoiding design problems. “We didn’t have to worry about extensive aftertreatments like similar engines in its horsepower range,” says Stinger Engineer Devin Ensminger. “The C9.3B does not have an exhaust gas return and is a more compact exhaust system, so it’s a little less complex than other engines with fewer things that can go wrong.”

“Having an integrated and very compact exhaust system helps with our application,” says Matlack. “A compact C9.3B that maintains EU Stage V, U.S. EPA Tier 4 Final emissions for such a wide range of horsepower and torque options is very appealing to Stinger.”

STREAMLINING DESIGN WITH FOLEY POWER SOLUTIONS

Stinger’s Cat dealer, Foley Power Solutions, continues to be integral in the further development of the 6500 and 8500 Stinger Stackers. “Early in the design, we identified space-claim challenges because of the shape of the stackers,” says Foley OEM Accounts Manager Ed Beatty. “We were able to outline solutions and put together a suitable engine spec.” When Stinger had technical questions about implementing Cat engines into its applications, Foley provided quick responses. “There have been some challenges I’ve put Foley through,” says Ensminger. “They’ve always given us what we needed or connected us with Cat engineers for assistance for our application.”

“The Cat dealer and off-site service techs and parts drop box network is also a very appealing benefit for our customers, many of whom are hours away from most major service facilities,” Matlack says. “When they have issues, having parts availability and techs arriving quickly is critical. The entire Cat network aligns well with where our machines are running, making it easier for Stinger customers to quickly and conveniently get the parts and service they need to get back in the field. Many of our customers had knowledge of Cat engines and their durability in other equipment and previous purchases. It was well received by our customers to go with Caterpillar,” says Matlack.

“We were able to outline solutions and put together a suitable engine spec.”

Stinger President, Karl Matlack

Cat Industrial Engine Support

Your Cat dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.