If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

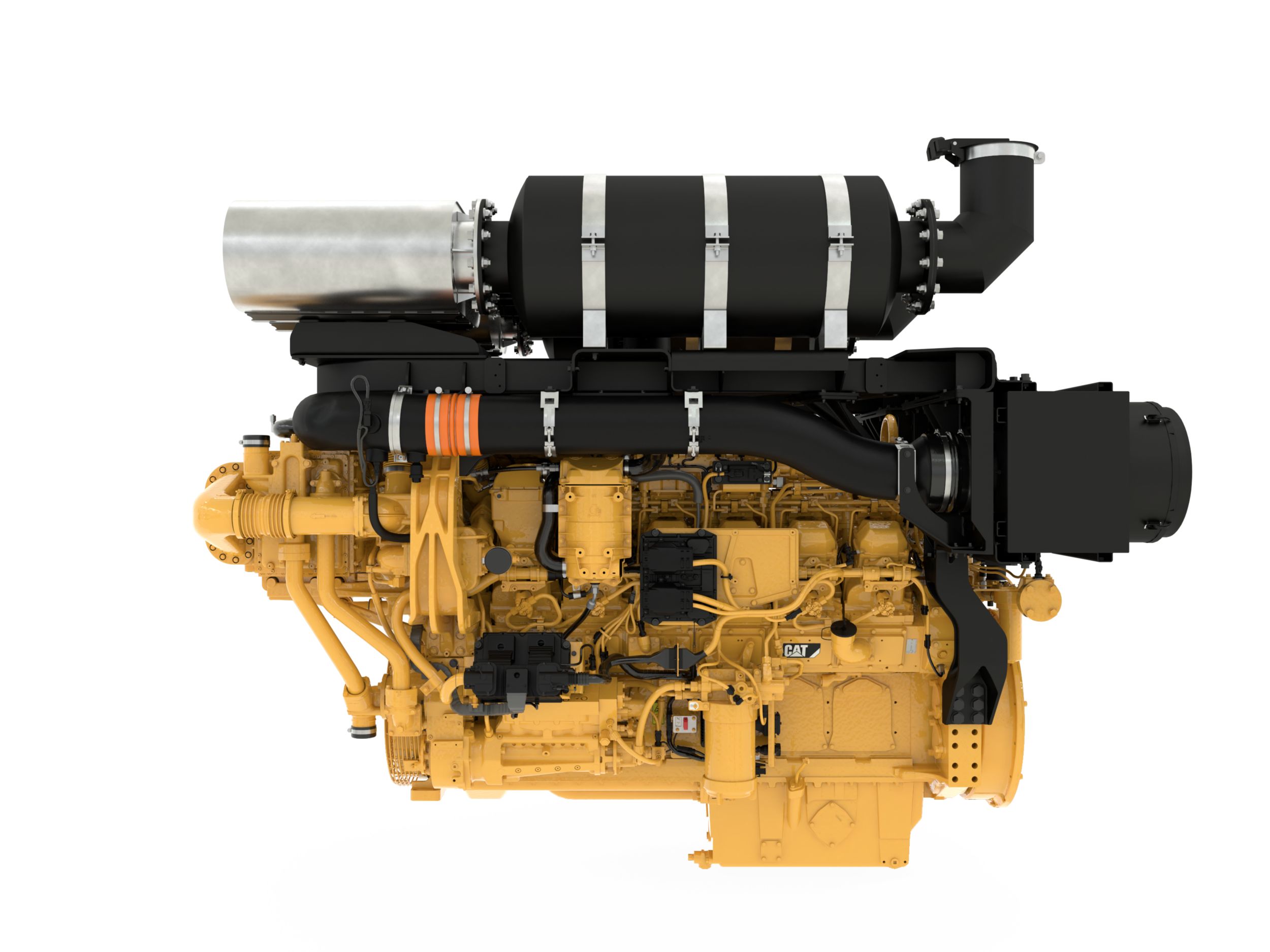

TECHNOLOGY DELIVERS HIGH DISPLACEMENT & LOW EMISSIONS

INDUSTRY-FIRST ADVANCES ON THE 3512E TIER 4 FINAL DGB™ ENGINE

How does the Cat® 3512E Tier 4 Final engine with Dynamic Gas Blending™ achieve the industry’s best diesel displacement, widest fuel flexibility and greatest greenhouse gas reduction? Through the use of some of the industry’s biggest technology advancements. Here are three of the most important:

1. In-Cylinder Pressure Sensing (ICPS)

ICPS monitors the pressure inside each cylinder, then precisely adjusts the gas flow to help you achieve the highest levels of diesel displacement — up to 85% — and fuel cost savings. Individually controlling combustion and monitoring pressure in each cylinder also helps you remain Tier 4 Final compliant.

2. Solenoid-Operated Gas Admission Valves

Solenoid Operated Gas Admission Valves are high-pressure gas-metering devices that control fuel injection through each cylinder. The 3512E Tier 4 Final DGB engine’s electronic control module determines how long each Solenoid Operated Gas Admission Valve is activated to admit the proper amount of gas into each cylinder. By controlling fuel flow into the cylinder precisely, Solenoid Operated Gas Admission Valves optimize engine performance for high fuel efficiency and low emissions.

3. Engine Idle Reduction System (EIRS)

Exclusive to Caterpillar on the 3512E Tier 4 Final DGB engine, EIRS reduces nonproductive idle time by automatically shutting down the engine between pumping stages. On a 16-unit frac rig fleet, it could decrease idle by 60% — cutting fuel consumption by 3-5% over the course of a year. EIRS also cuts your maintenance costs because your power train accumulates fewer hours.

But that’s not all. Just like its Tier 4 Final diesel equivalent, the 3512E DGB engine also features:

- High-pressure common-rail fuel system with full electronic injection that’s easy to disassemble and service

- High-pressure fuel pump that provides best-in-class rail pressure to keep NOx and particulate matter emissions down

- Single-stage turbochargers that significantly reduce complexity and turn exhaust air into power

- NOx Reduction System with three Exhaust Gas Recirculation (EGR) coolers and an active heat shield that reduce in-cylinder temperatures to meet emission standards

Find out more about the technology advancements available on the new 3512E Tier 4 Final DGB engine — and how they can help you lower diesel consumption, emissions and operating costs. Get in touch with your local Cat dealer for all the details.

RELATED ARTICLES

-

2019-07-12 Reports From The Field: The Cat® 3512E Tier 4 Final DGB Engine

July 12, 2019

What do well service operations already using the new Cat® 3512E Tier 4 Final engine with Dynamic Gas Blending (DGB) have to say about its performance? Watch to find out.

Learn More -

2020-10-02 Tier 4 Final DGB™ Field Gas Project Is a Success

October 02, 2020

See how Cat® Dynamic Gas Blending™ engines and GTUIT mobile gas treatment delivered big fuel savings, emission reductions and safety benefits on a Texas frac site.

Learn More -

2020-09-10 3512E Dynamic Gas Blending Engine

September 10, 2020

No engine on the market can match the 3512E Tier 4 Final DGB Well Service engine. Industry-best diesel displacement and fuel flexibility mean you save more without giving up diesel performance.

Learn More -

2019-07-12 3 Things To Know About The Cat® 3512E Tier 4 Final DGB Engine

July 12, 2019

Dynamic Gas Blending can get complicated. This video makes it easy to understand the top features and benefits of our newest Cat® 3512E Tier 4 Final DGB engine engine for well service.

Learn More