Assist features help make work easier, especially for less experienced operators. Some blade and steering functions are automated so newer operators can work at productivity levels closer to their veteran counterparts. Seasoned operators can enjoy reduced effort and fatigue, along with faster, more accurate results.

- Cat Grade with Slope Assist™ automatically maintains pre-established blade position without a GNSS/GPS signal – no additional hardware or software needed. For machines with 3D, operators can easily switch back and forth from full 3D automatics to Slope Assist.

- Steer Assist automates track and blade tilt steering. Helps reduce operator fatigue by automatically maintaining straight travel with light loads or heavy loads on flat ground and side slopes. Helps reduce steering inputs up to 75%. No GNSS/GPS required.

- Stable Blade works seamlessly with operator inputs to help produce a smoother surface when operating manually.

- Blade Load Monitor gives you real-time feedback on current load versus the optimal blade load based on your ground conditions. Actively monitors machine load and track slip to help you reach optimal pushing capacity.*

- Traction Control automatically reduces track slip to save you time, fuel and track wear.*

- AutoCarry automates blade lift to help you maintain consistent blade load and reduce track slip.*

- Slope Indicate is included in the main machine display and shows side slope and uphill/downhill grades to help operators with slope work.

- Attachment Ready Option (ARO) provides wiring and mounting provisions for dealer installation of Grade with 3D, Accugrade, UTS, or other grade control systems.

*Feature not operational indoors or in areas where a GNSS/GPS signal is not available.

Cat Assist and Grade technologies work in the background to help dozer operators of varied skill levels and are especially beneficial to less experienced operators. To demonstrate just how much these built-in technology features help, Caterpillar put them to the test. Two novice operators and two expert operators took on slot dozing, truck dump spreading/grading in sand, and side slope work. Each operator completed three runs of each task – one in manual, one using Assist technology features, and one using Assist plus Cat Grade with 3D. The team measured productivity*, efficiency**, completion time, final surface quality, and operator inputs.

Slot Dozing• Productivity and Efficiency – Novice operators went from 9% lower productivity and efficiency than the experts in manual to matching the experts when using Assist.

Truck Dump Spreading/Grading in Sand• Completion Time – Novice operators took 49% more time than the experts in manual and narrowed the gap to 17% using Assist and to 9% by adding Grade.

• Blade Inputs – Novice operator blade inputs were reduced 45% with Assist, and 55% with Assist plus Grade. Expert operator blade inputs were reduced 32% with Assist, and 53% with Assist plus Grade.

• Surface Quality – Novice operator surface quality improved up to 51% using technology while expert operator surface quality improved up to 27% using technology. Novice operators using technology produced similar surface quality to the expert operators in manual.

Side Slope/Steer Assist• Steering Inputs – Novice and expert operator steering inputs reduced by 75% in forward and by 67% combining forward and reverse.

*Material moved per hour

**Material moved per unit of fuel/Diesel Exhaust Fluid (DEF)

Study conducted by Caterpillar, August 2022

- Optimize machine performance for greatest productivity, while helping improve fuel efficiency and reduce greenhouse gas emissions with a fully automatic 3-speed transmission with lock-up clutch.

- The Cat® C7.1 engine meets U.S. EPA Tier 4 Final, EU Stage V, Japan 2014 and Korea Tier 5 emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) ** or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Cat® Grade with Slope Assist™ helps you avoid costly rework and wasteful fuel burn and greenhouse gas emissions by automating your blade position without a GPS signal.

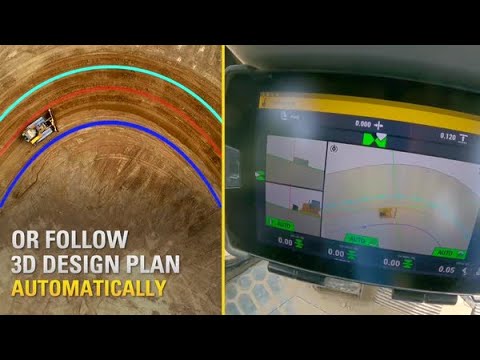

- Cat® Grade with 3D automates blade movements using a GPS signal helping you follow a grade design, reducing fuel burn and greenhouse gas emissions by improving efficiency and accuracy.

- AutoCarry™ automates blade lift to reduce track slip for maximum efficiency on each pass to help lower fuel burn and greenhouse gas emissions.

- VisionLink® displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

All comparisons to D6N T4F. Productivity, fuel and CO2 emissions vary by application. CO2 emissions calculations based on a reference work cycle using 2.2 U.S. gallons per hour of #2 U.S. diesel fuel. Applies IPCC2006 methodology using U.S. EPA Emissions Hub emission factors. Includes DEF (diesel exhaust fluid) related CO2. Fuel measurements are at 15°C. Estimated average fuel consumption improvements are based on tests or Product Link™ data where available. Productivity improvements are based on test data.

**Engines with no aftertreatment devices can use higher blends, up to 30% biodiesel.