Power Rating

| Maximum Power | 416 hp 310 kW |

| Maximum Torque | 1335 lb-ft @ 1400 rpm 1810 Nm @ 1400 rpm |

| Rated Speed | 1800-2200 rpm 1800-2200 rpm |

| Minimum Power | 308 hp 230 kW |

Key Specs

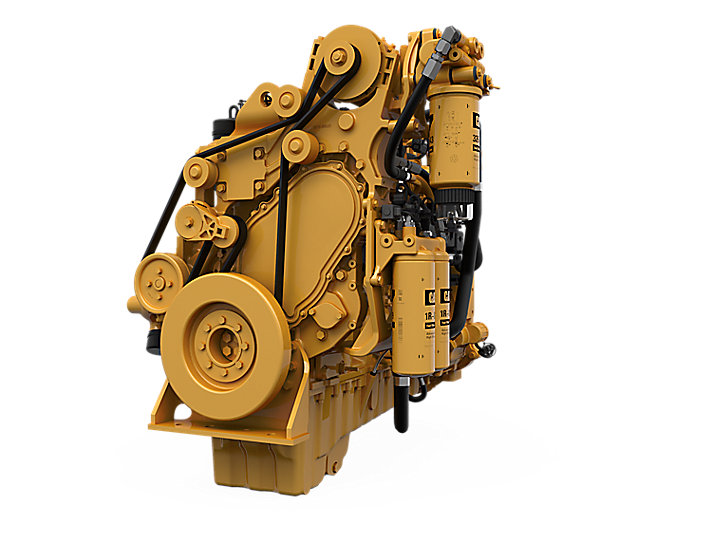

The Cat?� C9.3B industrial diesel engine is offered in ratings rangingfrom 280-330 kW (375-443 hp). These ratings have been fuel optimized

for use in countries without any regulatory requirements for emissionstandards.

| Maximum Power | 416 hp 310 kW |

| Maximum Torque | 1335 lb-ft @ 1400 rpm 1810 Nm @ 1400 rpm |

| Rated Speed | 1800-2200 rpm 1800-2200 rpm |

| Minimum Power | 308 hp 230 kW |

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

| Length | 44 in 1125 mm |

| Width | 31 in 791 mm |

| Height | 42 in 1068 mm |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 1907 lb 865 kg |

| Engine Configuration | Inline 6, 4-Stroke-Cycle Diesel Inline 6, 4-Stroke-Cycle Diesel |

| Bore | 4.5 in 115 mm |

| Stroke | 5.9 in 149 mm |

| Displacement | 567.5 in³ 9.3 l |

| Compression Ratio | 16.5:1 16.5:1 |

| Aspiration | Turbocharged Aftercooled (TA) Turbocharged Aftercooled (TA) |

| Combustion System | Direct Injection Direct Injection |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Aftertreatment | - - |

Use the comparison tool to compare detailed specs of Cat and competitor models.

Compare All ModelsCaterpillar product brochures and other informational documents are available for your growing business.