325 Heavy-Duty Undercarriage Configuration - Heavy-Duty Stability. Built for Demanding Terrain.*

- When the jobsite demands more muscle, the latest heavy-duty (HD) Cat 325 Excavator delivers. Built with an oversized long undercarriage and a robust 203 mm (8 in) track pitch, it’s engineered for outstanding stability and durability in harsh, uneven ground conditions.

- A 7,500 kg (16,350 lb) counterweight enhances balance and control, even when equipped with optional attachments such as a blade, Variable Angle boom, heavy-duty stick, bucket thumbs, or quick coupler. Advanced travel motors improve grade-climbing power, while upgraded swing motors and bearings ensure strong, smooth swing performance—even on slopes.

- Operators still get all the benefits they expect from a Cat 325: factory-integrated technology to boost productivity, extended maintenance intervals help keep owning and operating costs low, and electro-hydraulic efficiency ensures smooth, precise operation —all backed by Caterpillar’s proven electro-hydraulic system.

Machine Setup Simplification

- At the touch of fingertips and navigating user-friendly icons, the latest operator-oriented User Interface (UI) maximizes uptime and gets crews to work without delay. From re-ordering work tool lists to creating new work tool combinations as needed, operators can quickly set up machines and easily access information.

- The interface allows operators to maintain accuracy and makes the most of every second of their shift. Adding the ability to input couplers and attachments into the system makes setting up work tool combinations highly efficient by significantly reducing calibration time. It also eliminates the need to measure up again when changing Cat® work tool attachments and makes it manageable for a single person to check and adjust for bucket wear.

Cat®

Grade 3D Ready

- The Cat Grade 3D Ready option includes all the hardware required for the Grade with 3D system, installed and tested from the factory. This option provides an easier upgrade path for customers who want to add Grade with 3D after their initial purchase. To activate, contact your Cat Dealer to purchase the required 3D software licenses. Licenses can be installed remotely or manually loaded onto the machine.

Cat Payload and Advanced Payload**

- Cat Payload provides operators with on-the-go weighing to help them hit load targets and avoid overloading, underloading, or misloading materials. Advanced Payload is a system upgrade that offers expanded features and capabilities, including custom tags, daily totals, and electronic ticketing. Combine Payload with VisionLink™*** to analyze jobsites and individual assets for remote management of production targets and key metrics.

*Available in North America and Europe only.

**Payload technologies are not legal for trade.

***VisionLink subscription required.

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area.

Build Number: 07H

- The latest operator oriented User Interface (UI) has been designed to maximize uptime by allowing operators to easily reorder work tool lists and quickly create new work tool combinations. It also eliminates the need to measure up again when changing Cat® work tool attachments and makes it manageable for a single person to check and adjust for bucket wear.

- Cat® Lift Assist helps avoid machine tipping. With visual and auditory alerts, operators will know if their load is within the excavator’s safe working range limits.

- Cat® Grade with Assist helps operators stay on grade simply and effortlessly with semi-autonomous digging. It automates boom, stick, and bucket movements to deliver more accurate cuts with less effort.

- Cat® Grade with 2D for excavators is an indicate system that helps operators reach grade faster.* Select your target depth and slope and watch the Grade with 2D system use on-board processors and sensors to provide real-time guidance on the distance to grade.

- Cat® Grade with 3D for excavators helps operators grade more quickly, accurately, and efficiently, improving productivity. *It incorporates GNSS technology and RTK positioning guidance to streamline the grading process for complex designs commonly encountered on large infrastructure and commercial projects. This system allows operators to work confidently, eliminating guesswork while cutting and filling to precise specifications.

- The Cat® Grade 3D Ready option includes all the hardware required for the Grade with 3D system, installed and tested from the factory. Activation requires the purchase of additional 3D software licenses, contact your Cat Dealer for details.

- Upgrade to our dual antenna GNSS for maximum grading efficiency. The system lets you create and edit designs on the touchscreen monitor while you’re on the job, or you can have the plan design sent to the excavator to make your work easier. Plus, you get added benefits of avoidance zones, cut and fill mapping, lane guidance, and augmented reality along with advanced positioning capability.

- All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica. Already invested in a grade infrastructure? You can install grade systems from Trimble, Topcon, and Leica onto the machine.

- Cat® Payload provides operators with on-the-go weighing to help them hit load targets and avoid overloading, underloading, or misloading materials. Advanced Payload is a system upgrade that offers expanded features and capabilities, including custom tags, daily totals, and electronic ticketing. Combine Payload with VisionLink™** to analyze jobsites and individual assets for remote management of production targets and key metrics.

- Cat® Operator Coaching allows operators of all experience levels to take their efficiency and productivity to the next level. With tips and data at their fingertips, operators can track and improve their productivity through everyday work on the job site. Gain data-based insights towards operators and operations when you pair Operator Coaching with VisionLink™** There are two coaching tip categories –

- Operational Efficiency Tips: Help operators stay at the top of their game by identifying areas to increase skill and efficiency, such as digging technique and idle times.

- Machine Health Tips: Some actions are inefficient and cause unnecessary wear and tear on the machine and its components. Following Machine Health Tips can help extend the life of the machine, improve digging technique, and reduce fuel waste.

* Compared with traditional grading methods.

**VisionLink™ subscription required.

NOTE: Cat® Payload for excavators is not legal for trade. Availability may vary by region, consult your Cat Dealer for more details.

Tackle your jobs with a complete Cat® solution. Cat attachments are not just accessories – they are essential tools that define what your machine can do. When you pair a Cat excavator with Cat attachments, you unlock a fully integrated system built for performance, durability, and efficiency. Whether you are clearing land, breaking concrete, or compacting soil, the right attachment transforms your excavator into a powerful, multi-purpose tool ready for any challenge. Depending on your project or application, you could benefit from excavator attachments such as:

Buckets: Handle everything from digging and grading to cleanup and debris removal with your excavator. Caterpillar® offers general duty, heavy duty, extreme duty, and severe duty buckets, as well as specialized designs for ditch cleaning, rock, and finishing work. Reinforced edges and wear-resistant materials ensure long-lasting performance in tough conditions.

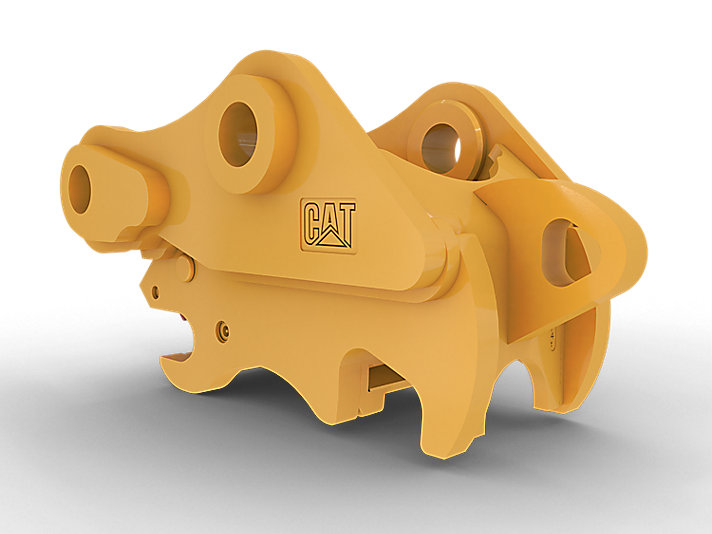

- Couplers (HEX): Cat® couplers for excavators enable fast, secure attachment changes, without the need to leave the cab. From Pin Grabbers to hydraulic quick connect options, couplers help reduce downtime, boost jobsite efficiency and promote versatility by allowing multiple machines to share a common attachment inventory.

- Hammers: Break concrete, rock, and steel with up to 1,000 blows per minute. Built for high-production demolition, quarrying, and construction, they offer powerful impact energy and consistent performance. Their durability and low-maintenance design make them essential for demanding breaking applications.

- Multi-Processors: A versatile tool for demolition, equipped with interchangeable jaws to handle concrete, steel, and rebar. Multi-Processors combine cutting, crushing and pulverizing capabilities in one attachment. Their modular design maximizes efficiency across a range of job site demands.

- Demolition and Sorting Grapples: Tackle larger debris or precisely sort materials into piles. These grapples are engineered for accuracy in demolition and material sorting, handling concrete, rebar, wood, and mixed debris. High clamping force and agile movement make them ideal for primary and secondary demolition and recycling operations.

- Scrap and Demolition Shears: Rotating shears provide precision cutting for metal structures, pipes, rebar, and scrap, making them ideal for demolition and recycling. Their powerful jaws and fast cycle times ensure clean cuts and high productivity. Built for durability, they excel in heavy-duty steel processing.

- Pulverizers: Built to crush concrete and separate rebar during demolition and recycling. With high crushing force and fast cycle times, pulverizers efficiently reduce material for easier handling. Primary models feature 360° bidirectional rotation and tackle structure teardown, while secondary models have a fixed jaw design and process debris after demolition.

- Compactors (Vibratory Plate): Compact soil, sand, gravel and asphalt quickly and efficiently to create a stable foundation. Vibratory plate compactors deliver high-impact force and even coverage, reducing air pockets and improving surface integrity for trenching, roadwork, and patching.

- Rotary Cutters: Get accurate, precise work with less noise and vibration. Cat® Rotary Cutters deliver high torque and precision for a range of applications: demolition, grinding, profiling, trenching, tunneling, and quarrying. Specifically designed for excavator-mounted use to handle heavy-duty materials like concrete, rock, and dense brush with ease.

- Orange Peel Grapples: Built for scrap and bulk material handling, Orange Peel Grapples excel with irregular, heavy loads like metal, rock, and waste. Their hydraulic tines provide superior grip and penetration. High-capacity and continuous rotation are perfect for scrap yards and transfer stations. Caterpillar® offers these grapples with a choice of different shell designs and tine options suited to various applications.

- Thumbs: Add gripping capability to your buckets, enabling precise and secure handling of irregular materials like rocks, stumps, and debris. Perfect for loading, sorting, and placing tasks, they enhance versatility and control. Hydraulic or mechanical options allow for flexible operation across job types.

- Tiltrotators: Tiltrotators provide 360° rotation and 40° left/right tilt functionality, allowing attachments to move with unmatched precision and flexibility. This flexibility transforms your machine into a multi-functional tool capable of working from virtually any angle without repositioning. Ideal for grading, trenching, and complex excavation work, they deliver multi-angle control for tight and confined spaces.

Cat® attachments are engineered to maximize your excavator’s productivity, helping you get more work done with greater efficiency and confidence. Choosing the right attachment is not just about compatibility, it is about unlocking your machine’s full potential while avoiding equipment damage or safety risks. Connect with your Cat Dealer to find the optimal attachments for your specific machine and application needs.

Please note: Not all attachments are available in all regions. Contact your Cat Dealer for details.

325 Heavy Duty Undercarriage Configuration

Built for Tough Jobs with Excellent Stability & Durability

The latest Heavy-Duty long undercarriage offers outstanding stability, especially in rough or uneven terrain. Pair that with the optional HD stick, and you’re getting a machine built to handle demanding applications with minimal downtime, helping to reduce maintenance costs and extend the life of your investment.

Ready-to-Work Attachments Save Time & Money

The 325 comes Thumb-Ready and with a Quick Coupler Circuit pre-installed. That means fast attachment changes and no need for costly aftermarket modifications. You get flexibility right off the factory floor — whether you’re switching between buckets, thumbs, or other tools.

Power That Pays Off

With its high drawbar pull, the 325 effortlessly climbs steep grades, ensuring productivity at any site.* Thanks to its enhanced swing torque, you can move material quickly — even uphill — resulting in fast cycle times and increased work completed in less time.

Bottom Line: Low Owning and Operating Costs + More Uptime = A Smart Investment for Any Fleet

The latest 325 isn’t just another excavator — it’s a compact radius machine that packs heavy-duty performance, integrated technology, and unmatched versatility.

*7500 kg (16,540 lb) counterweight with a heavy-duty undercarriage versus the 325 with an 8300 kg (18,300 lb) counterweight and standard undercarriage. Unchanged uphill capabilities for other configurations.

Available in North America and Europe only.