Experience hybrid-like fuel efficiency with an intelligent hydrostatic power train and industry leading fuel savings through a lower maximum engine speed of just 1,600 rpm in Standard Mode. Power when you need it with Caterpillar's exclusive Power‑by-Range technology that increases power in Range 4 for improved speed on grade. For your toughest and most demanding farm applications a new Performance Mode will allow you to boost the power and hydraulic speed in all Ranges to get the job done even quicker. Meets EU Stage V emission standards with a Cat® C7.1 engine that is designed to manage itself so you can concentrate on your work.

Move more with Caterpillar's patented quick loading Performance Series buckets and optimized Z-bar linkage that combines the digging efficiency of a traditional Z-bar with tool carrier capabilities. The parallel lift throughout the working range allow you to safely and confidently handle loads from bales to silage with precise control. Multi-function work has never been easier with dedicated pumps for each system and a flow sharing implement valve governed by an intelligent power management system. Simultaneously lift, steer and drive without compromise.

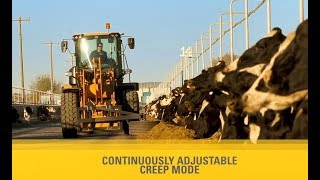

Have a seat in the 926M Ag Handler and enjoy automatic temperature control, class leading sound levels, excellent all around visibility and low-effort joystick controls that move with you on a fully adjustable seat suspension. A large spacious operator environment combined with Caterpillar's exclusive hydraulic cylinder damping and smooth predictable controls make this the most comfortable seat on the farm.

Fine tune machine performance with adjustments at your fingertips through the soft touch buttons and optional secondary touch screen display. Quickly set auxiliary flow to optimize grapple or silage defacer speed, enable auto reversing fan to breathe clean in dusty environments, toggle over to fine mode for improved control when bale stacking, program linkage kick-out positions for easy feed wagon loading, adjust wheel torque to match underfoot conditions when cleaning corrals and customize ride control activation speed for a smooth loaded carry run. The 926M Ag Handler is ready for the challenge on your farm!