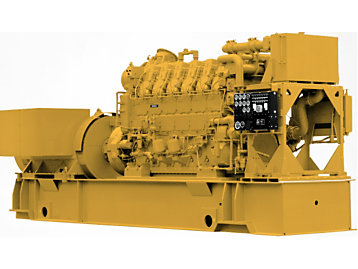

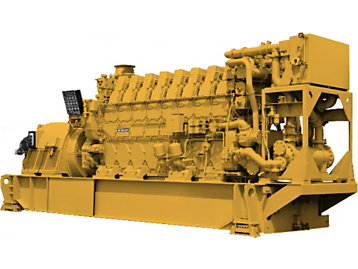

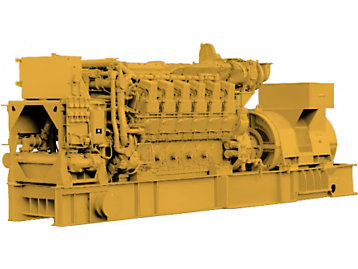

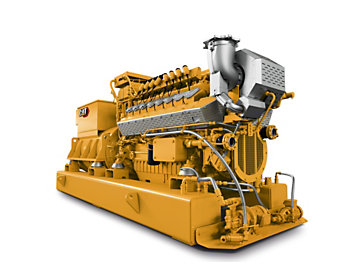

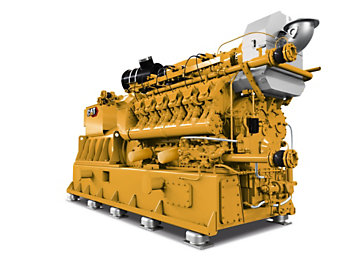

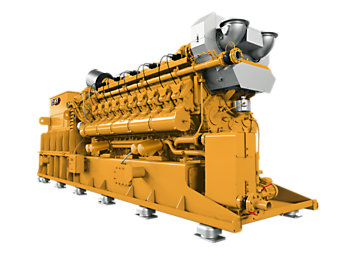

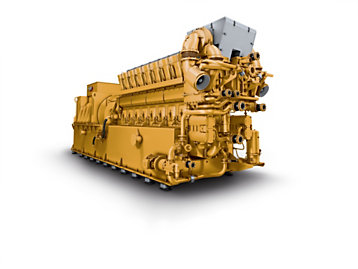

Generator Set Specifications

| Maximum Rating | 60 ekW 60 ekW |

| Minimum Rating | 36 ekW 36 ekW |

| Emissions/Fuel Strategy | U.S. EPA Cert., Tier 3 U.S. EPA Cert., Tier 3 |

| Voltage | 208 to 600 Volts 208 to 600 Volts |

| Frequency | 60 Hz 60 Hz |

| Speed | 1800 rpm 1800 rpm |

| Duty Cycle | Standby, Prime Standby, Prime |